Hi Flow Stroller Technical Service Manual • PN 14314465 Rev

F

32

H

i F

lo

w S

tr

oller

Repair Procedures

X

RP27 – Case Cleaning

a. Clean using household glass cleaner or Simple Green D and

lint-free cloth. Do not get glass cleaner inside case or onto any

plumbing components. Simple Green D is available at www.

simplegreend.com

b. If necessary, a soft bristle brush can be used to help remove dirt

and debris. If desired, Caire, Inc. Technical Service can sup-

ply a specific list of additionale reccommended cleaning tools.

c. Allow unit to dry thoroughly before filling.

RP28 – Normal Evaporation Rate Test

a. Fill unit following procedure found in the Patient Operating

Instructions (POI).

b. Push button and check that all 8 LEDs are on, or verify that

the spring scale reads full.

c. Check for leaks in QDV and vent valve.

d. Let unit sit 16–18 hours.

e. Make sure FCV and vent valves are closed.

f. Do not move unit during this time.

g. If the Hi Flow is at least half full (4 LEDs), the unit passes.

Maximum loss rate prior to dewar servicing is 1.75 lbs./day

(0,8 kg/day).

NOTE: Clean case only after unit is empty and warm. Do not

clean in oxygen enriched atmosphere.

NOTE: Only use disinfectants or cleaning agents approved

for use with this equipment by CAIRE such as Sporicidin®,

HydroPure®, Hydroklean®, or others as specified by CAIRE.

RP2

9

–

Relief Valve Test

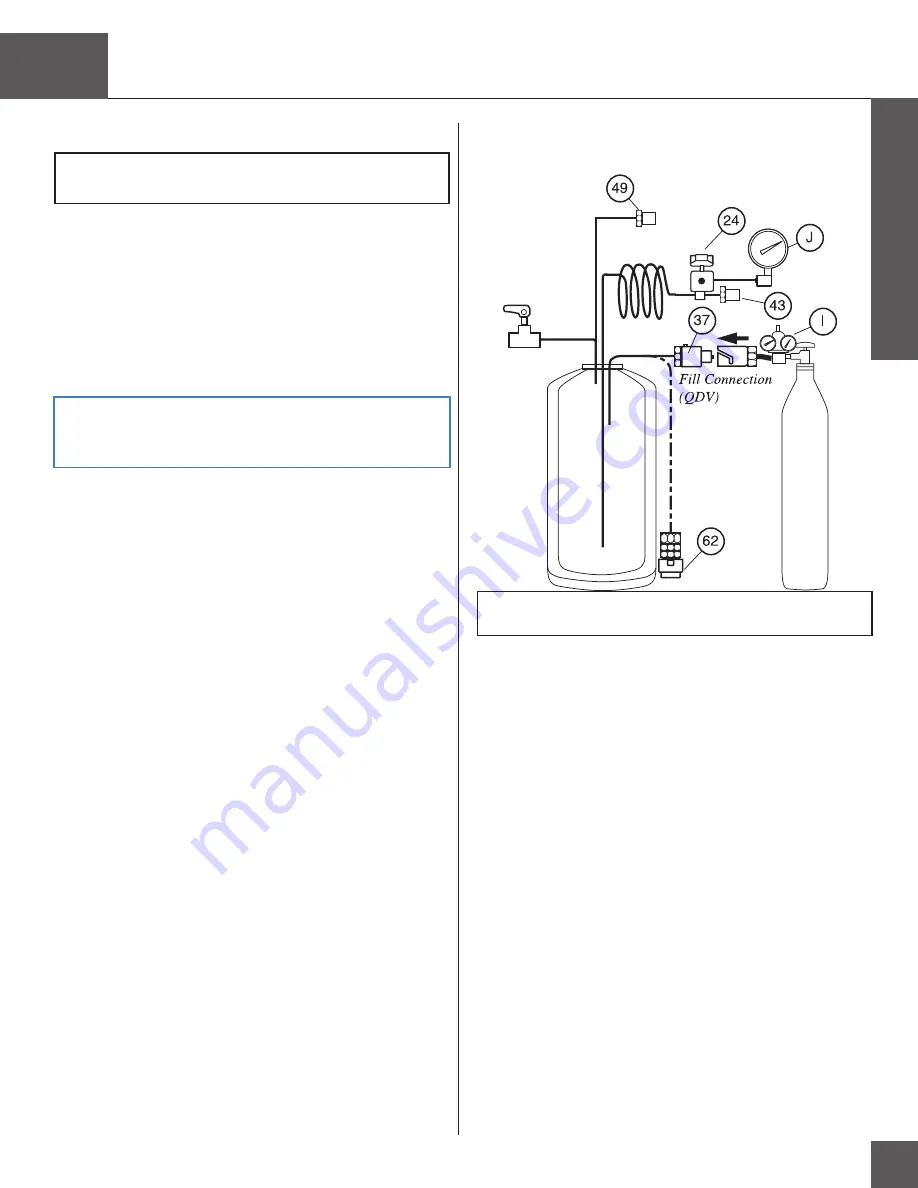

FIGURE

21

:

Relief Valve Test

WARNING:

The unit must be empty, warm and vented before

starting procedure.

a.

Remove case (RP4).

b.

Assemble pressure gauge (Item J) and adapter assembly.

Thread

hose barb onto pressure gauge. Push tubing onto hose

barb

and

attach with clamp.

c.

Assemble oxygen regulator, hose and pneumatic adapter.

Connect assembly to oxygen gas source. Connect pneumatic

adapter to unit QDV (Item 37

or 62

).

d.

Slowly begin increasing pressure to between 1,

35-1,4

8

bar/

19,7-2

1

,

5

psig. PRV (Item

49

) should begin venting

(audible noise will be heard or bubbling will be seen if leak

testing).

e.

Slowly begin decreasing the pressure until the PRV (Item

49)

closes, meaning the audible noise is no longer heard or the

bubbling is no longer seen if leak testing. The pressure at

which

the audible noise or bubbling is no longer seen should

be

greater than 1.

24

bar/

18

psig

.

f.

Hold PRV (Item 49) closed (with finger) and increase pres-sure

to 1,9-2,3 bar (27-33 psig). SRV (Item 43) must begin

open

(audible venting and/or bubbling of leak test solution).

g.

Slowly begin decreasing the pressure until the SRV

(Item 43)

closes, meaning the audible noise is no longer heard or the

bubbling is no longer seen if leak testing. The pressure at

which

the audible noise or bubbling is no longer seen should

be

greater than 1,

68

bar/2

4,3

psig

.

h.

Slowly begin decreasing the pressure

in order to release the

finger from the PRV.