1

HELiOS Portables Technical Service Manual • PN 20562190 Rev E

25

HELiOS P

or

tables

Troubleshooting & Repair Procedures

XI

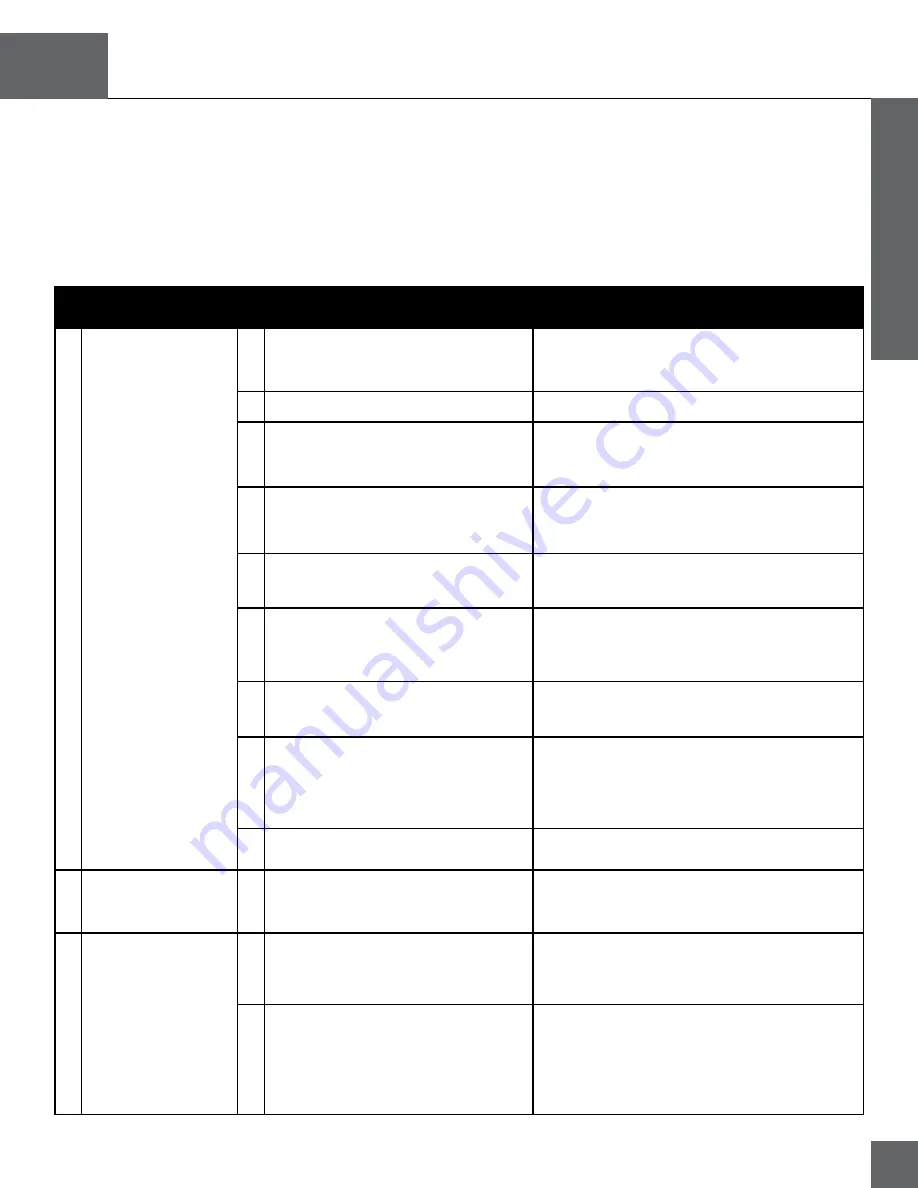

Table 6 below provides troubleshooting procedures for the HELiOS portables. This guide is not all-inclusive but is intended to serve

as a general outline for solving operational problems. The table describes symptoms, identifies probable causes, and suggests correc-

tive actions.

When more than one probable cause is identified, the causes are listed in order of most likely to least likely reasons for the problem.

Table 6:

Troubleshooting

Symptom

Probable Cause

Corrective Action

1) Unable to start fill or

excessively long fill

times

a) QDV not properly engaged on the reser-

voir

Make sure the QDV on the portable and reservoir are

properly aligned and ensure that a downward force is

being applied to the portable.

b) Reservoir is empty

Swap or re-fill the reservoir

c) Vent valve not open

Ensure that the vent valve lever is fully in the open

position. The lever must be open to begin a fill.

d) FCV is open

Be sure that the FCV knob is in the off (“0”) posi-

tion. If the valve is open, fill times can increase.

e) Reservoir saturation pressure is too low

Swap reservoirs or allow the reservoir time to stabi-

lize and build pressure

f) Vent valve is obstructed

Inspect the vent tubes for blockages. Clean by blow-

ing out with compressed gas or replace parts if nec-

essary.

g) Leak in the system

Check the portable for leaks (RP2) and repair if

needed.

h) QDV damaged or faulty

Inspect the QDV and be sure the poppet opens prop-

erly and smoothly. If necessary, replace the QDV

assembly (RP17)

i) Faulty vent valve

Replace the vent valve (RP15)

2) Liquid leaks from the

coupled QDVs during

the fill

a) Worn or damaged lip seal

Replace the QDV lip seal (RP18)

3) Unable to disconnect

the portable from the

reservoir

a) Pop-off assembly not being utilized

Ensure that the pop-off assembly on the reservoir is

being used. Do not use force to separate the QDVs.

b) QDVs are frozen together

Leave the units coupled with the vent valve closed

and let them sit until they warm up enough to discon-

nect. Always ensure that male and female QDV’s

are cleaned and dried prior to each fill.