6

6

2

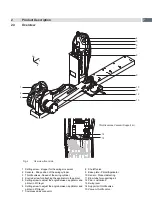

Product Description

2.1

Important Features

•

The supporting air and the vacuum as well as the speed of the cylinder are adjustable. That way the applicator

can be adapted to different label materials and sizes.

•

To avoid contamination within the vacuum channels they are cleaned by air pressure impulse at the end of each

application.

•

For operation in a system the I/O interface of the printer can be used.

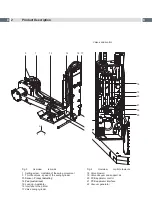

2.2

Technical Data

Label transfer mode

Tamp pad

Spring loaded tamp pad

Blow pad

3014/16 L/R 1100

3014/16 L/R 3100

3014/16 L/R 2100

Label width in mm for 4

25 - 114

80 - 114

25 - 114

for 6

25 - 174

80 - 174

-

Label height in mm

25 - 250

80 - 250

25 - 100

Compressed air pressure

0.45 MPa (4.5 bar)

Sound pressure level

under 74 dB(A)

Product during

labeling

fixed

¢

¢

¢

in motion

¢

¢

¢

Labeling onto the

product

from the top

¢

¢

¢

sideways

¢

¢

¢

from the front

¢

¢

¢

from the back

¢

¢

¢

Product height

variabele

¢

¢

¢

Length of swing lever

2)

mm

200/300/400

200/300/400

200/300/400

Swing angle

0-90°

0-90°

0-90°

Cycle time about frequency/min.

1)

15

15

15

Table 1

Technical Data

1)

Determined with 100 mm lever length / label height / print speed 100 mm/sec.

2)

Length of swing lever: achievable labeling position of 90° (bottom edge of label) below the ground.