19

6.3

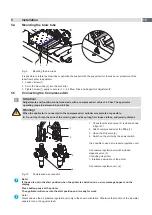

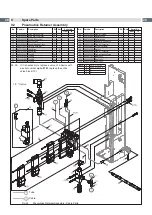

Adjusting the sensors of the swing cylinder

6

7

8

9

1

3

2

4

5

Fig. 16

Adjusting the sensors of the swing cylinder

Close the pressure air support.

Switch on the printer.

The sensors (4 and 9) detect the end position of the swing cylinder movement.

The generated signal is necessary for the next steps in the operation process.

-

Sensor (4) is switched: pad is in start position and the print and labeling process can start.

-

Sensor (9) is switched: pad is in labeling position. The application of the label will start via the product sensor.

Swing the pad assembly in the used position.

Loosen screw (3 or 7) and make a first adjustment. The damper on the setting screw is full pressed in in this

position.

Tighten screw (3 or 7) .

Loosen screw (2 or 8) and move the sensor (4 or 9) so that the sensor will trigger sure via the switch arm (5) .

It is to see on the glowing of the LED on the sensor.

If the pad assembly has leave the end position, the LED at the sensor does not glow .

Tighten screw(2 or 8) .