Discharge connection

CAUTION

Do not put hands into the outlet aperture.

Risk of body damage !

The following instructions for connection to the discharge side only

apply if the drawn gas is discharged into a suitable environment by the

vacuum pump.

l

Make sure that the protection that was fitted to prevent the

ingress of particles during transport has been removed before the

vacuum pump is connected up to the vacuum pipe

l

Make sure that the nominal diameter of the discharge line

corresponds at least to the diameter of the exhaust flange of the

vacuum pump in order to prevent a drop in the performance of the

vacuum pump, in case of use of a smaller cross-section

CAUTION

When the discharge piping has been connected up, make sure that

the system does not leak. Leakage of dangerous substances must be

prevented!

l

Make sure that the discharge line is fitted in such a way as to

prevent any liquids or condensates to re-enter the vacuum pump

(siphon, discharge line sloping away from the pump)

l

Make sure that the discharge line is not equipped with a shut-off

device

l

Make sure that the discharge line does not exercise any pressure

onto the exhaust flange. Use bellows if necessary

l

The outlet flange has the following dimension:

–

DN 80 PN6 or ISO-K DN 63

l

Maximal counter pressure at the discharge:

–

0,1 bar

In the case of long discharge lines, the line cross-section should be

larger than the exhaust flange in order to prevent a drop in the

performance of the vacuum pump. If you have any doubts, contact

your Busch representative.

Electrical connection/ Checks

The electrical installation must only be carried out by a specialist.

The regulations according to European Standard EN 50081 and EN

50082 (electromagnetic compatibility), EN 60079 Part 17 and 19, as

well as EN 60204 (machine safety, electrical equipment of machines)

and VDE 0100 (setting up of high voltage equipment with nominal

voltages up to 1000 V) must be observed.

The end user’s mains supply must comply with the regulations

according to European Standard EN 50081 and EN 50082

(electromagnetic compatibility). If this is not the case, the manufacturer

of the vacuum system must be notified.

If the motor’s direction of rotation is wrong, the pump can be seriously

damaged.

In order to change the direction of rotation, two phases on the motor

must be swapped around.

l

Make sure that the requirements according to EMC-Directive

2014/30/EU as well as the current EN-standards, electrical and

occupational safety directives and the local or national regulations

respectively, are complied with (this is the responsibility of the

designer of the machinery into which the vacuum pump is to be

incorporated; see also the corresponding comments in the

EU-Declaration of Conformity)

l

Make sure that the power supply is compatible with the data on

the nameplate of the drive motor

l

Make sure that an overload protection according to EN 60204-1 is

provided for the drive motor

l

Make sure that the drive of the vacuum pump will not be affected

by electric or electromagnetic interference; if unsure please seek

advice from your Busch representative

Cooling liquid level control

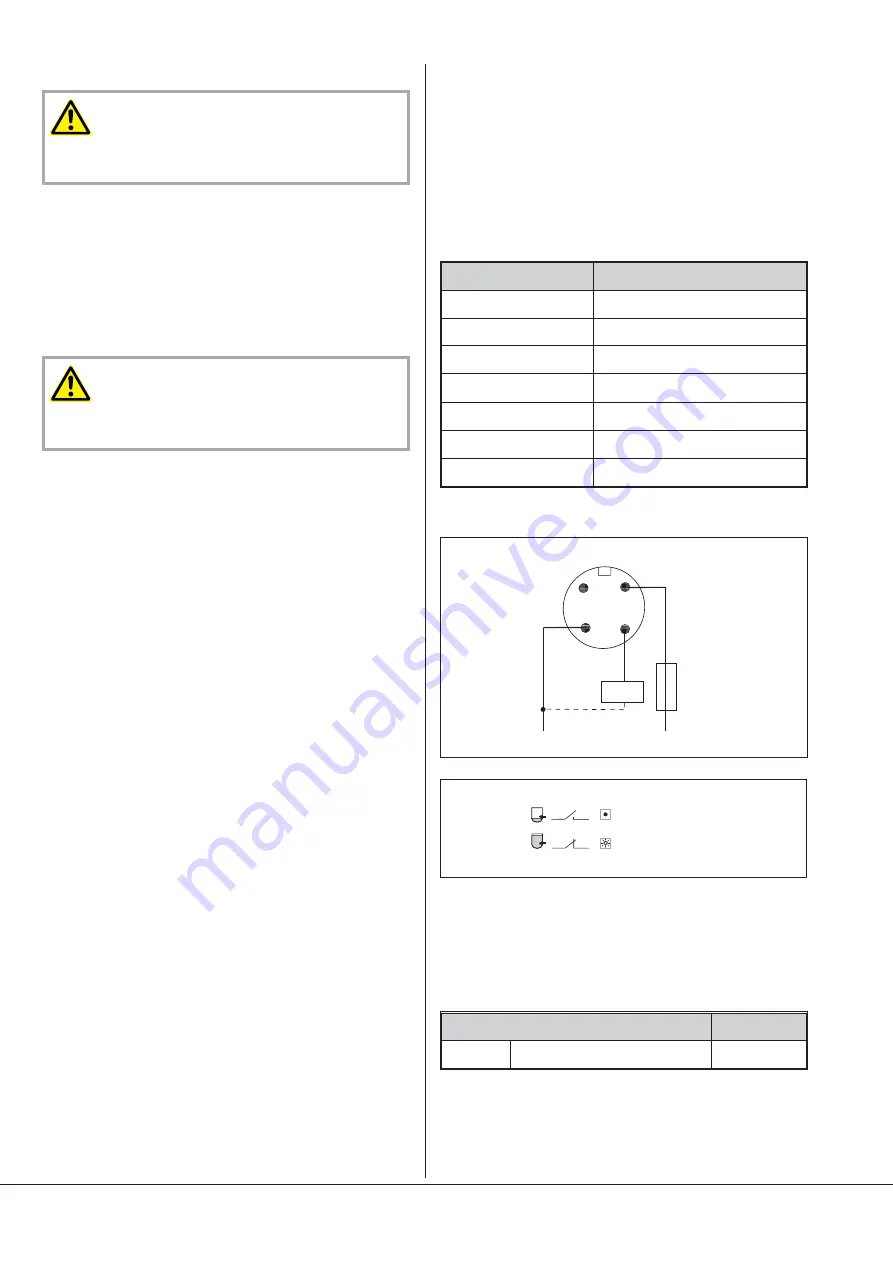

The cooling liquid level is supervised by a level switch LS that is

mounted in the inlet side cylinder cover.

The electrical connection of the level switch (LS) has to be done in such

a way that the vacuum pump stops when the level switch (LS) detects

a too low level of cooling liquid for moore than 30 seconds.

Technical data

Technical data

Level switch LS

Type

Liquiphant FTL31-AA4M3AAW5J

Breaking capacity

200 mA

Current consumption

< 15 mA

Power consumption

< 975 mW

Range

> 0,7 g/cm

3

Supply voltage

10...30 VDC

Connector

M12 x 1 Type Binder

Electrical wiring diagram

Cooling Liquid Temperature Monitoring

The cooling liquid temperature is monitored by a PT100 temperature

sensor (TS).

The PT100 temperature sensor (TS) must be electrically connected in

such a way that the vacuum pump stops if the cooling liquid

temperature exceeds 65°C.

Designation

Set value [°C]

TS

PT 100 Cooling liquid temperature

65

Installation and Commissioning

Page 8

1 : BN

2

3 : BU

4 : BK

0.5 A

L +

L -

K

1

4

1

4

LED not lit (red)

LED lit (yellow)

Summary of Contents for 7180551

Page 24: ......

Page 26: ...Temperature sensor TS Temperature sensor TS Page 26...

Page 27: ...Temperature sensor TS Page 27...

Page 28: ...Temperature sensor TS Page 28...

Page 29: ...Temperature sensor TS Page 29...

Page 34: ...Note...

Page 35: ...Note...