37

3) Assembly of Metal-Fab Corr/Guard Vent System:

a) Corr/Guard General Notes:

• Do not cut Corr/Guard vent components.

• Refer to Corr/Guard installation instructions for proper methods of support.

• Orient Corr/Guard components so that the males ends of all fittings point in the direction of the boiler.

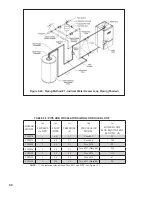

b) Start assembly of the vent system at the boiler. Remove the hose clamp shipped on the FCM vent collar. Bend the three

hose clamp tabs on this collar outward slightly.

c) Clean the exterior of the male end of the first piece of pipe and the inside of the vent collar on the boiler. Remove dirt,

grease, and moisture from the surfaces to be sealed. Dry surfaces or allow to dry thoroughly.

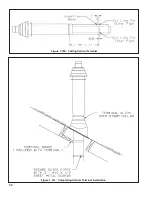

d) On the male end of the pipe, apply a ¼” wide bead of silicone approximately ½” from the end of the pipe (see Figure

7.47).

e) Insert the male end of the pipe into the boiler vent collar until it bottoms out.

f) Apply an additional bead of silicone over the outside of the joint and smooth out.

g) Replace and tighten the clamp on the vent collar.

h) Assemble remaining Corr/Guard components in accordance with the Corr/Guard installation instructions.

i) Allow the silicone to cure per the silicone manufacturer’s instructions before operating the boiler.

Figure 7.7: Corr/guard Connection to Vent Collar

Summary of Contents for FREEDOM

Page 8: ...8 Figure 1 Wall Mounting Hole locations ...

Page 9: ...9 Figure 5 2 Boiler Mounting Hardware ...

Page 11: ...11 Figure 6 1 Boiler Installed In A Confined Space Ventilation Air From Inside ...

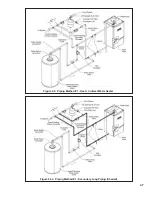

Page 42: ...42 FIGURE 7 51 CONDENSATE PIPING ARRANGEMENT ...

Page 55: ...55 Figure 10 1 Wiring Connections Diagram ...

Page 56: ...56 Figure 10 2 Ladder Diagram ...

Page 57: ...57 Figure 10 3 Wiring of Isolation Relay for Control of Two Heating Circulators ...

Page 60: ...60 FCM Series Lighting and Operating Instructions ...

Page 66: ...66 FIGURE 12 2 BASIC MENU TREE ...

Page 75: ...75 ...

Page 77: ...77 ...

Page 79: ...79 ...

Page 80: ...80 ...

Page 81: ...81 ...

Page 83: ...83 150 151 152 153 154 155 ...

Page 84: ...84 156 157 158 159 160 161 ...

Page 85: ...85 162 ...