9

MAINTENANCE

The weaver unit should be periodically checked and cleaned to maximize service life.

Before use:

Check all screws in the torch clamp. Tighten as needed. Loose fasteners may cause inconsistent

weld quality.

During use:

Monitor motor and welding torch for abnormal noise or overheating.

After each use:

1. Clean control panel to remove dust and other debris.

2. Inspect slide adjustment and torch for weld spatter or other debris. Clean as needed.

3. Inspect power cable and torch cable for cracked, cut or damaged insulation. Replace as needed.

4. Inspect connectors for damaged pins or loose connections. Replace as needed.

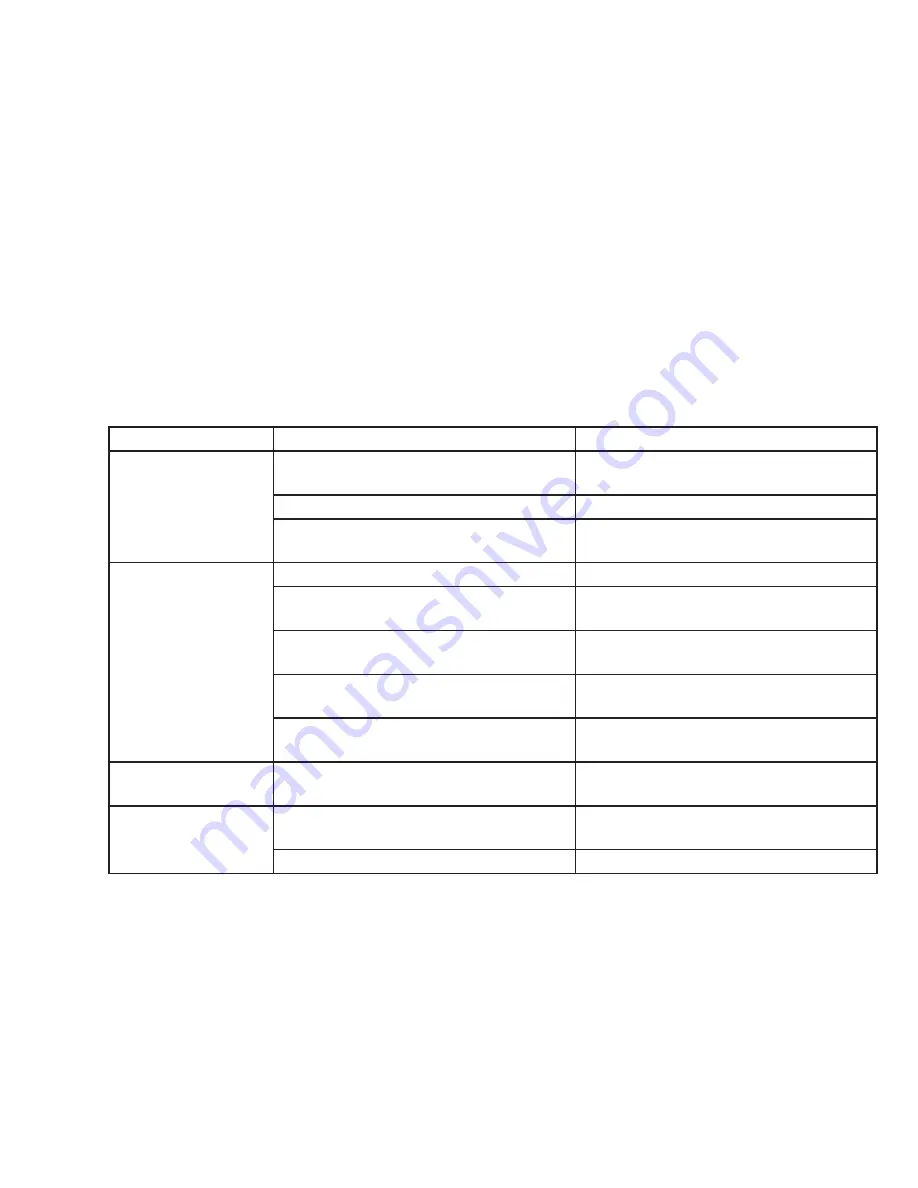

TROUBLESHOOTING

Symptom

Cause

Repair

Control Pendant

Display is not LIT

Disconnected Power Cable

Verify power cable is properly

connected to machine.

Faulty Power Cable

Replace cable.

Control Pendant Fuse Tripped or

Disconnected

Replace fuse. If problem persists,

contact service rep.

No Arc when Start

button is pressed

Weld Contact switch set to OFF

Turn Weld Contact switch to AUTO.

Loose contact of Welding Leads

Check ground connections. Verify good

contact on clean, unpainted surface.

Bad or incorrectly wired Weld Contact

switch

Check Wiring. Replace switch, if

needed.

Weld Contact Cable is bad or

improperly connected

Verify cable is correctly connected.

Replace cable if bad.

Weld Power Source turned OFF

Turn ON Weld Power Source

Torch targets wrong

position

Loose fastener on Torch Clamp

Check and tighten screws, replace if

needed.

Arc continues after

Stop button is

pressed

Crater Fill timer has not timed out.

Check timer settings and adjust if

needed.

Faulty or incorrectly wired Stop button

Check Wiring. Repair as needed.