Description

2

CLS Pro 600 – Line and Contrast Sensor

17/108

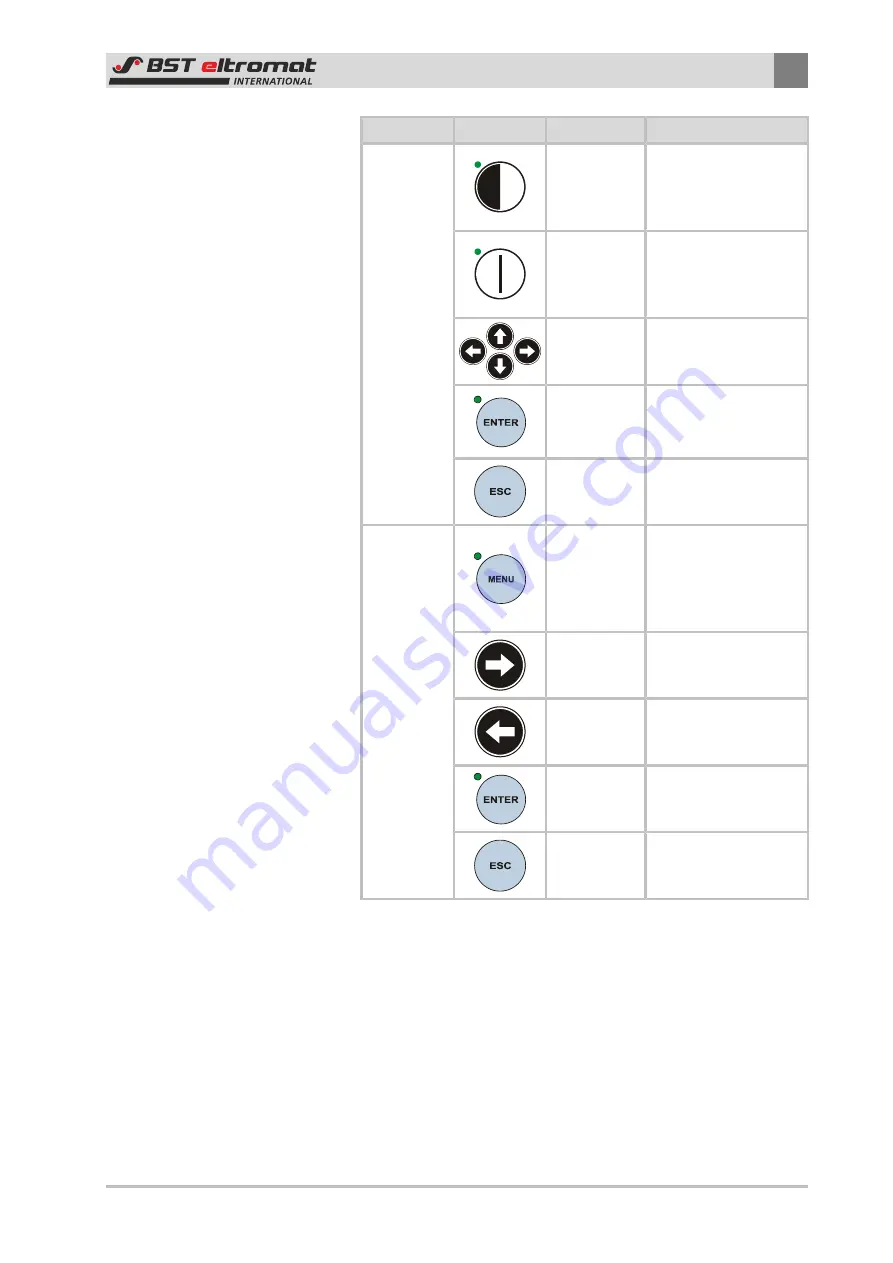

Function

Key

Designation

Description

Setup

Mode

Edge SETUP

Calls up the edge guid-

ing setup mode (only

possible in

MAN

mode)

Line SETUP

Calls up the line guid-

ing set-up mode (only

possible in

MAN

mode)

Arrow Keys

Used to enter settings

as shown in the oper-

ating help page

ENTER

■

Imports the mode /

parameter settings

■

Exit the Setup mode

ESC

Aborts the parameter

entering process

Menu

MENU

Calls up or exits the

quick menus (the key

must be held down for

at least 3 seconds to

call up the menu)

Right Arrow

Key

Used to enters a sub-

menu or parameter

Left Arrow

Key

Pages back by one

menu level (does not

exit the menu)

ENTER

Used to open a sub-

menu or select a para-

meter

ESC

Pages back by one

menu level and might

also close the menu

2.6

Safety Information

The safety relevant information in accordance with DIN EN ISO

13857, DIN EN 349 and the industry specific accident prevention

regulations must always be taken into consideration when in-

stalling the BST-eltromat equipment in the production machine,

these include:

■

There must always be a safe distance between the BST-eltro-

mat equipment and the machinery already installed on-site,

such as machine panels, building structures, etc.