935CA: Installation, Start-up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

19

A200088

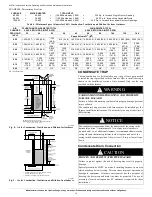

Fig. 32 – Working Platform for Attic Installation

NOTE:

Furnace shown is a direct vent application. Refer to the venting

section for allowable vent configurations.

NOTE:

N Coil only, add 8-in. separation between coil and furnace for

all other unshielded coils, see evaporator coil spacer or shield

requirements.)

NOTE:

Local codes may require a drain pan and condensate trap when a

condensing furnace is installed over a finished ceiling.

A200085

Fig. 33 – Suspended Furnace Installation

NOTE:

Furnace shown is a direct vent application. Refer to the venting

section for allowable vent configurations.

NOTE:

N Coil only, add 8-in. separation between coil and furnace for

all other unshielded coils, see evaporator coil spacer or shield

requirements.)

NOTE:

Local codes may require a drain pan and condensate trap when a

condensing furnace is installed over a finished ceiling.

Supply Air Connections

For a furnace not equipped with a cooling coil, the outlet duct shall be

provided with a removable access panel. This opening shall be

accessible when the furnace is installed and shall be of such a size that

the heat exchanger can be viewed for possible openings using light

assistance or a probe can be inserted for sampling the air stream. The

cover attachment shall prevent leaks.

Connect supply-air duct to flanges on furnace supply-air outlet. Bend

flange upward to 90° with wide duct pliers, see

Fig. 27

. The supply-air

duct must be connected to ONLY the furnace supply-outlet-air duct

flanges or air conditioning coil casing (when used). DO NOT cut main

furnace casing side to attach supply air duct, humidifier, or other

accessories. All supply-side accessories MUST be connected to duct

external to furnace main casing.

Return Air Connections

The return-air duct may be connected to bottom of the furnace. The side

of casing that faces downward may also be used for return air

connection. A combination of the bottom and downward facing side may

also be used. The upward facing side of the casing cannot be used as a

return air connection, see

Fig. 29

.

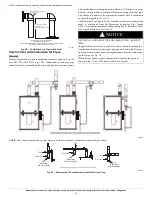

Bottom Return Air Inlet

These furnaces are shipped with bottom closure panel installed in bottom

return-air opening. Remove and discard this panel when bottom return

air is used. To remove bottom closure panel, see

Fig. 34

.

Side Return Air Inlet

These furnaces are shipped with bottom closure panel installed in bottom

return-air opening. This panel MUST be in place when side return air

inlet(s) are used without a bottom return air inlet.

Not all horizontal furnaces are approved for side return air connections,

see

Fig. 29

. Where required by code, seal bottom closure to furnace with

tape, mastic, or other durable sealing method.

A170123

Fig. 34 – Removing Bottom Closure Panel (2 Screws)

Filter Arrangement

There are no provisions for an internal filter in these furnaces. An

external filter rack is required and is purchased separately. A field

supplied accessory air cleaner may also be used in place of the filter

rack.

For upflow applications, the filter can be installed on either side of the

furnace, the bottom of the furnace or any combination of side and

bottom of the furnace, see

Fig. 28

.

For horizontal applications, the filter rack (or field supplied accessory air

cleaner) can be connected to the bottom opening on the furnace. For side

ADDITIONAL 1” CLEARANCE BELOW TRAP RECOMMENDED

FOR SERVICE

6-3/8” CLEARANCE

NEEDED FOR TRAP

NOTE

: FURNACE SHOWN IS A DIRECT VENT APPLICATION. REFER TO THE

VENTING SECTION FOR ALLOWABLE VENT CONFIGURATIONS.

NOTE

:

(N

COIL

ONLY,

ADD

8"

SEPARATION

BETWEEN

COIL

&

FURNACE

FOR

ALL

OTHER

UNSHIELDED

COILS)

SEE EVAPORATOR COIL SPACER OR

SHIELD REQUIREMENTS.

6-3/8” CLEARANCE

NEEDED FOR TRAP

ADDITIONAL 1”

CLEARANCE BELOW TRAP

RECOMMENDED

FOR SERVICE

WARNING

!

FIRE, CARBON MONOXIDE AND POISONING

HAZARD

Failure to follow this warning could result in fire, personal injury or

death.

Never operate a furnace without a filter or filtration device installed.

Never operate a furnace with filter or filtration device access doors

removed.

1.

Lay furnace on the back or side

2.

Remove the two (2) screws that secure the bottom

closure panel to the furnace casing and remove the

panel

SCREWS (2)

BOTTOM

CLOSURE

Representative drawing. Models may vary.