935CA: Installation, Start-up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

14

A200077

Fig. 19 – Example of Tube Connection

Upflow Specific Steps – Standard Installation

1. Install trap adapter to the collector box using provided machine

screw, see

Fig. 14

.

2. Screw the adapter plate to the trap adapter using provided machine

screw, see

Fig. 15

.

3. Screw the adapter plate to the side of casing using six (6) of the

provided sheet metal screws, see

Fig. 15

. Drilling pilot holes is

recommended to better align the plate with the knockout opening.

4. Screw the trap to the adapter plate using provided machine screw,

see

Fig. 15

.

5. Remove factory-installed collector box cap. Run tube from port on

upper left of the collector box to the relief port on the trap adapter,

see

Fig. 19

. If the tube is too long, cut any extra length from the

tube.

Upflow Specific Steps – Offset Installation

1. Trap Offset Adapter Accessory Kit (purchased separately) is

required. Instead of installing the trap to the adapter plate, screw the

trap offset adapter to the adapter plate, see

Fig. 16

.

2. Screw the trap to the trap offset adapter, see

Fig. 16

.

3. Screw the trap adapter plate to the casing using the supplied sheet

metal screw, see

Fig. 16

.

4. Remove factory-installed collector box cap. Run tube from port on

upper left of the collector box to the relief port on the trap adapter,

see Fig 19. If the tube is too long, cut any extra length from the

tube.

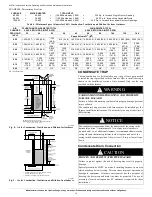

Horizontal Specific Steps

1. Accessory Horizontal Installation Kit (trap grommet) is required for

all direct-vent horizontal installations (only). The kit contains a

rubber casing grommet designed to seal between the furnace casing

and the condensate trap, see

Fig. 20

.

A200067

Fig. 20 – Horizontal Right - Trap Assembly Aid

2. Install the grommet in the casing when required for direct-vent

horizontal applications.

3. Allow for 6-3/8” (162 mm) of clearance underneath the furnace for

the condensate trap and drain line. It is recommended to leave an

additional 1” clearance under the trap for service, see Fig 21.

4. Remove appropriate collector box drain plug, see Fig 13.

5. Attach trap to collector box using provided machine screw, see Fig

20.

6. For horizontal right side down:

a. Remove factory-installed collector box cap.

b. Remove the factory-installed cap from the relief port on the trap

and run tube from port on the collector box corner opposite of the

trap to the relief port on the trap, see

Fig. 20

. If the tube is too

long, cut any extra length from the tube. In the installed position,

the transducer tubing should be in the lower pressure port and the

relief tubing should be in the higher port.

A200066

Fig. 21 – Trap Clearance in Horizontal Application

(Note: Drain line can be run horizontally or vertically)

NOTE:

Field Supplied Drain can be routed horizontally from the trap,

allow at least 1/4-in. per foot of slope down.

A200125

Fig. 22 – Horizontal Left - Trap Assembly Aid

7. For horizontal left side down:

a. Remove factory-installed collector box cap.

b. Remove the factory-installed cap from the relief port on the trap

and run tube from port on the collector box corner opposite of the

trap to the relief port on the trap, see Fig 22. This will require

removing the transducer pressure tubing from the

factory-installed position. If the tube is too long, cut any extra

length from the tube.

c. Install transducer pressure tubing on the collector box port

closest to the trap where the factory-installed collector box cap

was installed, see Fig 22. Trim transducer pressure tubing length

ensuring no traps of loops for extra water collections. In the

installed position, the transducer tubing should be in the lower

pressure port and the relief tubing should be in the higher port.

It is permissible to run the trap up to 5 ft. away from the furnace to an

area with the required trap clearance provided the following steps and

conditions are followed.

NOTICE

!

Extra water in transducer pressure tubing may inhibit furnace operation

because of incorrect pressure readings.