935CA: Installation, Start-up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

53

(1.)Remove thermostat from subbase or from wall.

(2.)Connect an amp. meter (see

Fig. 69

) across the R and W/W1

subbase terminals or R and W/W1 wires at wall.

(3.)Record amp. draw across terminals when furnace is in heating

and after blower starts.

(4.)Set heat anticipator on thermostat per thermostat instructions

and install on subbase or wall.

A96316

Fig. 69 – Amp. Draw Check With Ammeter

a. Electronic thermostat: Set cycle rate for 4 cycles per hr.

2. Cooling On Delay is fixed at 2 seconds for either jumper selection.

Check Safety Controls

1. Check Main Limit Switch(es)

This control shuts off combustion control system and energizes

air-circulating blower motor, if furnace overheats. By using this

method to check limit control, it can be established that limit is

functioning properly and will operate if there is a restricted duct

system or motor failure. If limit control does not function during

this test, cause must be determined and corrected.

a. Run furnace for at least 5 minutes.

b. Gradually block off return air with a piece of cardboard or sheet

metal until the limit trips.

c. Unblock return air to permit normal circulation for 5 minutes.

d. Main limit circuit open causes 3 hour lock out.

e. Reset unit power to clear limit fault lockout.

Checklist

1. Put away tools and instruments. Clean up debris.

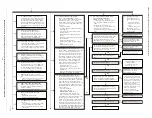

2. Verify that switches SW1-1 and SW1-6 are

OFF

and other setup

switches are set as desired. Verify that switches SW1-7 and SW1-8

for the blower

OFF DELAY

are set as desired per

Table 25

.

3. Verify that blower and control doors are properly installed.

4. Verify that there are no unsealed openings in the blower shelf or

casing.

5. Cycle test furnace with room thermostat.

6. Check operation of accessories per manufacturer’s instructions.

7. Review Owner’s Manual with owner.

8. Attach literature packet to furnace.

9. Attach entire literature packet to furnace.

SERVICE AND MAINTENANCE PROCEDURES

Untrained personnel can perform basic maintenance functions such as

cleaning and replacing air filters. All other operations must be performed

by trained service personnel. A qualified service person should inspect

the furnace once a year.

General

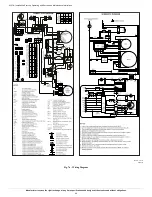

These instructions are written as if the furnace is installed in an upflow

application. An upflow furnace application is where the blower is

located below the combustion and controls section of the furnace, and

conditioned air is discharged upward. Since this furnace can be installed

in any of the 3 positions (see

Fig. 4

), you must revise your orientation to

component location accordingly.

CAUTION

!

FURNACE OVERHEATING HAZARD

Failure to follow this caution may result in reduced furnace life.

Recheck temperature rise. It must be within limits specified on the

rating plate. Recommended operation is at the mid-point of rise range

or slightly above.

R Y W G

10 TURNS

THERMOSTAT SUBBASE

TERMINALS WITH

THERMOSTAT REMOVED

(ANITICIPATOR, CLOCK, ETC.,

MUST BE OUT OF CIRCUIT.)

HOOK-AROUND

AMMETER

EXAMPLE:

5.0 AMPS ON AMMETER

10 TURNS AROUND JAWS

=

0.5 AMPS FOR THERMOSTAT

ANTICIPATOR SETTING

FROM UNIT 24-V

CONTROL TERMINALS

WARNING

!

FIRE, INJURY OR DEATH HAZARD

Failure to follow this warning could result in personal injury, death

and/or property damage.

The ability to properly perform maintenance on this equipment requires

certain knowledge, mechanical skills, tools, and equipment. If you do

not possess these, do not attempt to perform any service and

maintenance on this equipment other than those procedures

recommended in the Owner’s Manual.

CAUTION

!

ENVIRONMENTAL HAZARD

Failure to follow this caution may result in environmental pollution.

Remove and recycle all components or materials (i.e. oil, refrigerant,

control board, etc.) before unit final disposal.

WARNING

!

ELECTRICAL SHOCK, FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal injury or death,

or property damage.

Before installing, modifying, or servicing system, main electrical

disconnect switch must be in the OFF position and install a lockout tag.

There may be more than one disconnect switch. Lock out and tag

switch with a suitable warning label. Verify proper operation after

servicing. Always reinstall access doors after completing service and

maintenance.

CAUTION

!

ELECTRICAL OPERATION HAZARD

Failure to follow this caution may result in improper furnace operation

or failure of furnace.

Label all wires prior to disconnection when servicing controls. Wiring

errors can cause improper and dangerous operation.