935CA: Installation, Start-up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

30

A190371

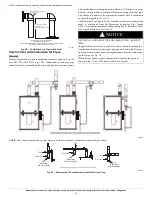

Fig. 47 – Two-Stage Thermostat with 1-Speed Variable Furnace and

Two-Speed Air Conditioner

NOTES FOR THERMOSTATS

1. Heat pump MUST have a high pressure switch for dual fuel

applications.

2. Refer to outdoor equipment Installation Instructions for additional

information and setup procedure.

3. If the heat pump date code is 1501E or earlier, select the “ZONE”

position on the two-speed heat pump control. Heat pumps having

date codes 1601E and later do not have or require a “ZONE”

selection.

4. Outdoor Air Temperature Sensor must be attached in all dual fuel

applications.

5. Dip switch No. 1 on Thermidistat should be set in OFF position for

air conditioner installations. This is factory default.

6. Dip switch No. 1 on Thermidistat should be set in ON position for

heat pump installations.

7. Dip switch No. 2 on Thermidistat should be set in OFF position for

single-speed compressor operation. This is factory default.

8. Dip switch No. 2 on Thermidistat should be set in ON position for

two-speed compressor operation.

9. Configuration Option No. 10 “Dual Fuel Selection” must be turned

ON in all dual fuel applications.

10. NO connection should be made to the furnace HUM terminal when

using a Thermidistat.

11. Optional connection: If wire is connected, ACRDJ jumper on

furnace

control

should

be

removed

to

allow

Thermidistat/Thermostat to control outdoor unit staging.

12. The RVS Sensing terminal “L” should not be connected. This is

internally used to sense defrost operation.

13. DO NOT SELECT the “FURNACE INTERFACE” or “BALANCE

POINT” option on the two-speed heat pump control board. This is

controlled internally by the Thermidistat/Dual Fuel Thermostat.

14. Dip switch D on Dual Fuel Thermostat should be set in OFF

position for single-speed compressor operation. This is factory

default.

15. Dip switch D on Dual Fuel Thermostat should be set in ON position

for two-speed compressor operation.

VENTING

NOTE:

Planning for the venting system should be done in conjunction

with planning for the ductwork, drainage, and furnace accessories, such

as air cleaners and humidifiers. Begin assembling the venting system

AFTER

the furnace is set in place in the required orientation.

Venting for this furnace shall follow all Local codes for Category IV

venting systems. This furnace is CSA approved for venting with

PVC/ABS DWV venting systems. This furnace is also CSA approved

for venting with M&G DuraVent

R

PolyPro

R

or Centrotherm

InnoFlue

R

polypropylene venting systems using single wall straight and

flex, and required fittings (elbows, reducers, increasers, connectors,

adapters) only.

NOTE:

THESE INSTRUCTIONS

DO NOT

CONTAIN DETAILED

INSTALLATION INSTRUCTIONS FOR POLYPROPYLENE

VENTING SYSTEMS. Refer to the polypropylene venting system

manufacturer’s installation instructions for the polypropylene venting

system installation.

NOTE:

When using polypropylene venting systems, all venting

materials used, including the vent terminations, must be from the same

manufacturer.

See notes 2, 11

WARNING

!

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each appliance connected

to the venting system being placed into operation could result in carbon

monoxide poisoning or death.

The following steps shall be followed for each appliance connected to

the venting system being placed into operation, while all other

appliances connected to the venting system are not in operation:

1. Seal any unused openings in venting system.

2. Inspect the venting system for proper size and horizontal pitch, as

required in the National Fuel Gas Code, ANSI Z223.1/NFPA 54 or

the CSA B149 Natural Gas and Propane Installation Code and

these instructions. Determine that there is no blockage or

restriction, leakage, corrosion and other deficiencies, which could

cause an unsafe condition.

3. As far as practical, close all building doors and windows and all

doors between the space in which the appliance(s) connected to

the venting system are located and other spaces of the building.

4. Close fireplace dampers.

5. Turn on clothes dryers and any appliance not connected to the

venting system. Turn on any exhaust fans, such as range hoods and

bathroom exhausts, so they are operating at maximum speed. Do

not operate a summer exhaust fan.

6. Follow the lighting instructions. Place the appliance being

inspected into operation. Adjust the thermostat so appliance is

operating continuously.

7. Test for spillage from draft hood equipped appliances at the draft

hood relief opening after 5 minutes of main burner operation. Use

the flame of a match or candle.

8. If improper venting is observed during any of the above tests, the

venting system must be corrected in accordance with the National

Fuel Gas Code, ANSI Z223.1/NFPA 54 and/or CSA B149.1

Natural Gas and Propane Installation Code.

9. After it has been determined that each appliance connected to the

venting system properly vents when tested as outlined above,

return doors, windows, exhaust fans, fireplace dampers and any

other gas-fired burning appliance to their previous conditions of

use.