30

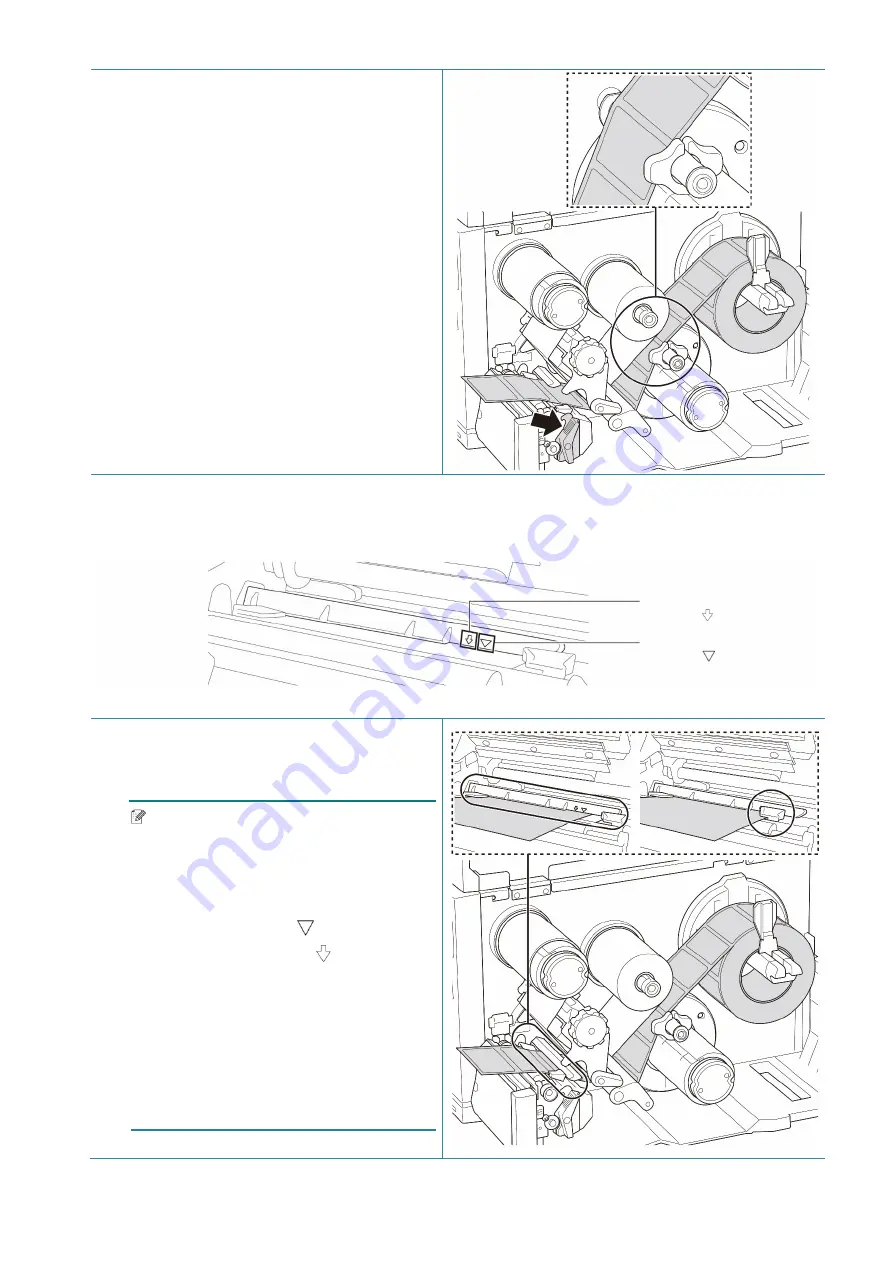

4. Push the Print Head Release Lever and

thread the label through the Damper,

Media Sensor, and Front Label Guide to

install the media.

5. Move the Media Sensor by adjusting the Media Sensor Position Adjustment Knob. Make sure

the position of the Gap or Black Mark Sensor matches the position of the Gap/Black Mark on

the label roll.

6. Adjust the Front Label Guide to fix the

media position.

Note

•

Make sure you thread the media

through the Media Sensor.

•

The sensor locations are marked by

the triangle mark (Gap Sensor)

and the arrow mark

(Black Mark

Sensor) at the sensor housing.

•

The Media Sensor position is

adjustable. Make sure the position of

the Gap or Black Mark Sensor

matches the position of the

Gap/Black Mark on the label roll.

Black Mark Sensor

(shown as )

Gap Sensor

(shown as

)