6. AIR PRESSURE MECHANISM

RH-981A

107

6. AIR PRESSURE MECHANISM

CAUTION

Maintenance and inspection of the sewing

machine should only be carried out by a

qualified technician.

Disconnect the air hoses from the air supply and

wait for the needle on the pressure gauge to drop

to “0” before disassembly of any parts which use

the pneumatic equipment.

Turn off the power switch before

disassembly, otherwise the machine may

operate if the start switch is pressed by

mistake, which could result in injury.

If the power switch and air need to be left on when

carrying out some adjustment, be extremely

careful to observe all safety precautions.

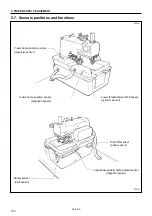

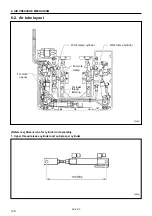

6-1. Solenoid valves and air tubes

6-1-1. Adjusting the solenoid valve speed controllers

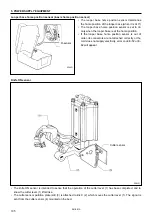

There are 3 speed controllers: No.3 (for lower thread trimming), No.5 (for upper thread trimming), and one for the knife.

1. As for the No.3 and No.5 speed controllers, adjust their heights to 10 mm.

Note:

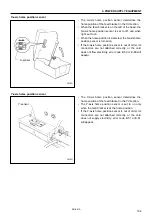

If the speed controllers are excessively throttled, error codes including E-75 (lower thread and operations

are incorrect) and E-76 (upper thread operation is incorrect), may appears.

2. The exhaust throttle valve is only attached to the OFF side of the knife valve. Adjust the protrusion of the speed

controller to 7.2 mm.

Note:

If the speed controllers are excessively throttled, error codes including E-72 (cutting block operation is

incorrect), may appear. If excessively opened, abnormal noise may be emitted when the knife cylinder

returns.

3545Q

3544Q