- 40 -

13.

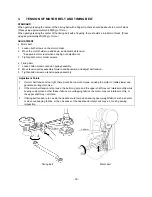

INNER ROTARY HOOK BRACKET POSITION

STANDARD

There should be 1.9-2.1mm overlap between inner rotary hook bracket spring and convex part of inner rotary

hook.

ADJUSTMENT

1.

Loosen screw on inner rotary hook bracket.

2.

Adjust the overlap so that it is 1.9-2.1mm between inner rotary hook bracket spring and convex part of inner

rotary hook.

3.

Tighten screw on inner rotary hook bracket.

14.

INNER ROTARY HOOK TENSION

STANDARD

Inner rotary hook tension should be 0.1-0.12N(10-12g) when #60 spun polyester thread is slowly pulled with a

tension gauge.

ADJUSTMENT

1.

Set a bobbin would properly with #60 spun polyester thread into the inner rotary hook, and pull thread slowly

with tension gauge.

2.

Use a screwdriver to turn spring adjustment screw to the left and right, and adjust thread tension.

* After making adjustments, be sure to lock adjustment screw using an oil based paint.

1.9-2.1mm

#60 spun polyester thread

10-12g

2

1

2

1

3

Summary of Contents for PE-300S

Page 1: ... 2 1999 ...

Page 4: ... 2 1 MECHANICAL CHART EMBROIDERY UNIT MECHANISM ...

Page 6: ... 4 3 ELECTRONIC PARTS ARRANGEMENT CHART ...

Page 7: ... 5 4 CONTROL SYSTEM BLOCK DIAGRAM ...

Page 11: ... 9 9 1 1 9 9 8 7 7 3 3 6 6 2 2 3 1 1 9 5 5 5 ...

Page 13: ... 11 12 11 17 20 20 15 16 19 20 18 13 14 10 10 ...

Page 15: ... 13 25 2 25 1 23 36 29 29 37 32 22 22 24 24 27 27 30 30 31 31 33 33 34 32 28 36 35 26 ...

Page 17: ... 15 39 39 38 ...

Page 19: ... 17 Diagram A 45 1 45 2 42 53 48 52 49 50 43 42 41 44 47 47 46 40 51 ...

Page 21: ... 19 Diagram A 55 60 56 54 58 64 64 65 61 61 59 59 54 57 ...

Page 23: ... 21 diagram A 74 69 69 68 69 75 73 72 70 67 67 ...

Page 25: ... 23 77 78 84 68 84 78 78 79 86 86 84 ...

Page 27: ... 25 5 3 2 2 2 2 3 4 1 5 ...

Page 28: ... 26 3 LEAD WIRE ARRANGEMENT ...

Page 57: ...PE 300S H8080132 ...