- 34 -

7.

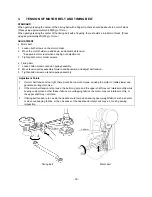

NEEDLE BAR HEIGHT

STANDARD

While in test mode (3) 3-point needle drop, select left needle drop, turn balance wheel with your hand so needle

(#11 needle) meets that outer rotary hook point. At this time, the distance between the top of the needle eye and the

bottom of the rotary hook point should be 1.0-1.4mm.

ADJUSTMENT

1.

Set machine to test mode and select (3) 3-point needle drop.

2.

Press the

mark on the screen to move the needle position to the right.

3.

Turn balance wheel so that needle meets outer rotary hook point.

4.

Loosen needle bar clamp screw.

5.

Raise and lower needle bar and adjust distance between top of needle eye and bottom of outer rotary hook

point so that it is between 1.0-1.4mm.

6.

Tighten needle bar clamp screw.

Adjustment Points

* When adjusting needle bar height, needle bar may turn easily, this could make sewing difficult. When

making these adjustments, make sure that front of needle clamp and feed dog grooves of needle plate

meet at a 90 degree angle.

* After adjusting needle bar height, check the vertical position of needle threading hook.

(1)

If needle bar is set at wrong height, skipped stitches, split thread, and thread breakage may result. (see

illustration below)

3-point needle drop screen

1.0-1.4mm

0mm

5

3

6

4

D

C

B

A

Summary of Contents for PE-300S

Page 1: ... 2 1999 ...

Page 4: ... 2 1 MECHANICAL CHART EMBROIDERY UNIT MECHANISM ...

Page 6: ... 4 3 ELECTRONIC PARTS ARRANGEMENT CHART ...

Page 7: ... 5 4 CONTROL SYSTEM BLOCK DIAGRAM ...

Page 11: ... 9 9 1 1 9 9 8 7 7 3 3 6 6 2 2 3 1 1 9 5 5 5 ...

Page 13: ... 11 12 11 17 20 20 15 16 19 20 18 13 14 10 10 ...

Page 15: ... 13 25 2 25 1 23 36 29 29 37 32 22 22 24 24 27 27 30 30 31 31 33 33 34 32 28 36 35 26 ...

Page 17: ... 15 39 39 38 ...

Page 19: ... 17 Diagram A 45 1 45 2 42 53 48 52 49 50 43 42 41 44 47 47 46 40 51 ...

Page 21: ... 19 Diagram A 55 60 56 54 58 64 64 65 61 61 59 59 54 57 ...

Page 23: ... 21 diagram A 74 69 69 68 69 75 73 72 70 67 67 ...

Page 25: ... 23 77 78 84 68 84 78 78 79 86 86 84 ...

Page 27: ... 25 5 3 2 2 2 2 3 4 1 5 ...

Page 28: ... 26 3 LEAD WIRE ARRANGEMENT ...

Page 57: ...PE 300S H8080132 ...