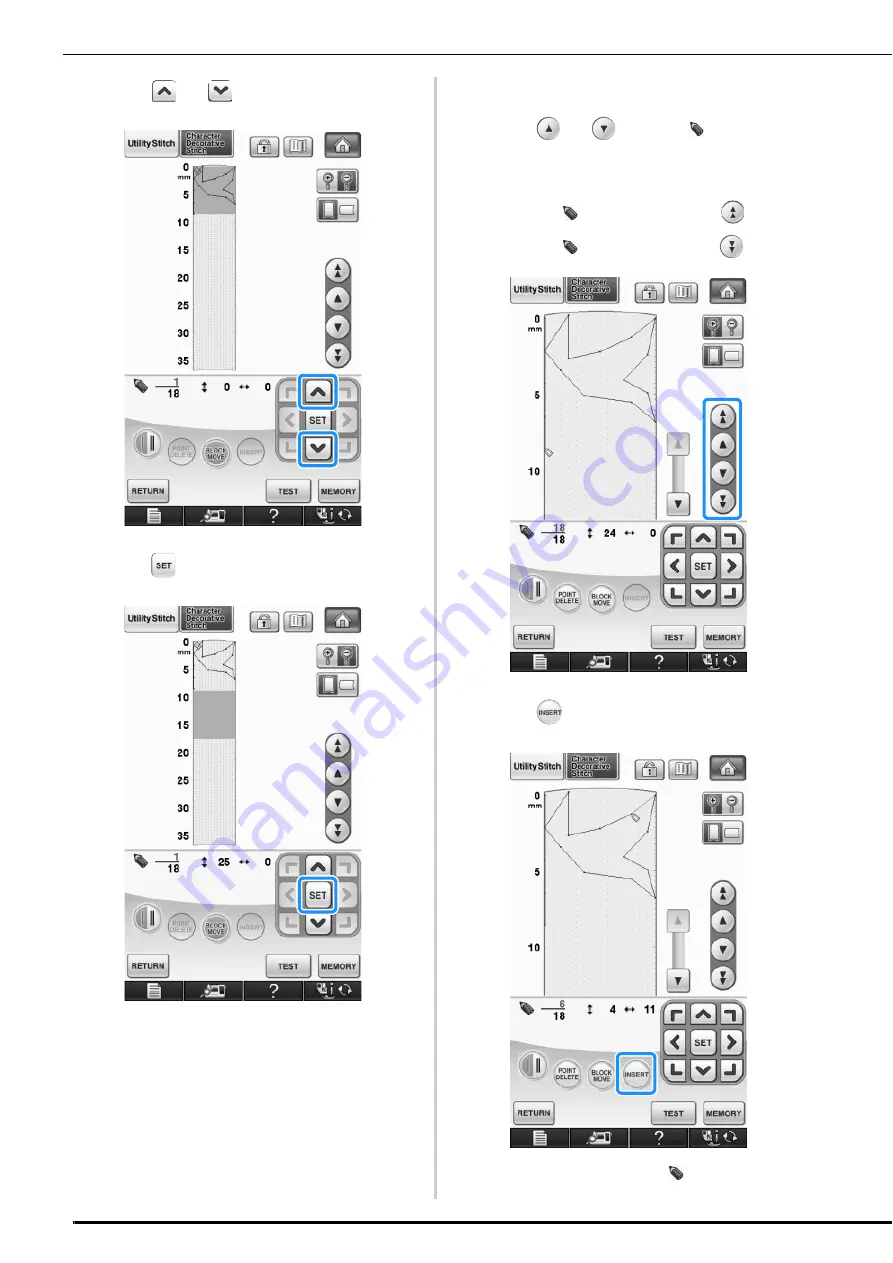

ENTERING STITCH DATA

332

c

Press

or

to move the section.

d

Press .

→

The section will be moved.

■

Inserting New Points

a

Press

or

to move

to a place on

the design where you want to add a new

point.

*

To move

to the first point, press

.

*

To move

to the last point, press

.

b

Press .

→

A new point is entered and

moves to it.

Summary of Contents for 882-W07

Page 72: ...CHANGING THE NEEDLE 70 ...

Page 90: ...USEFUL FUNCTIONS 88 ...

Page 186: ...USING THE MEMORY FUNCTION 184 ...

Page 326: ...TROUBLESHOOTING 324 ...

Page 338: ...USING STORED CUSTOM STITCHES 336 ...

Page 379: ......