72

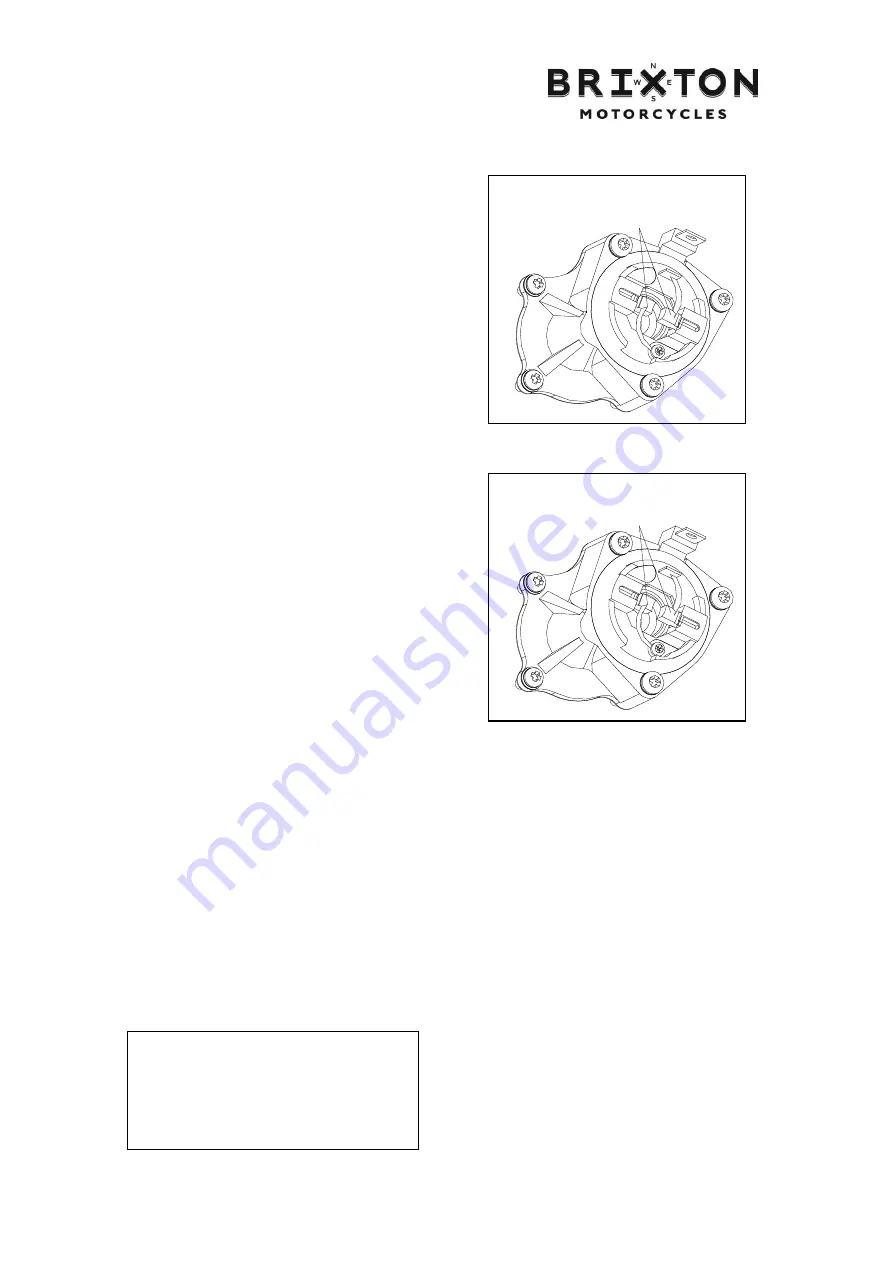

7.3.2 Disassembly

Disassemble housing screw, front cover, motor

housing and other parts.

7.3.3 Inspection

Inspect other component assemblies.

Replace with a new one when there is surface partial

friction, injuries or burning loss.

Commutator shall be cleaned when there is metal

particles adhered to its surface.

Inspect continuity between contact surfaces of

other assemblies.

Confirm uncontinuity of armature shaft among

surfaces of commutator.

Inspect continuity of starter motor housing.

Confirm uncontinuity between conducting terminal

and starter motor housing.

Inspect continuity between conducting terminal and brush.

Replace it with a new one if abnormality exits.

Inspect carbon brush holder for continuity. If there is continuity, replace it.

Measure carbon brush length

Service limit: replace it when it is shorter than 8.5mm

Check rotation smoothness of the needle bearing in the front cover and whether it is loosened

when it is pressed in.

If there is abnormality, replace it with a new one.

Check whether the oil seal is worn or damaged.

7.3.4 Assembly

Apply lubricating grease on the oil seal in the front cover.

Install brush onto the carbon brush holder.

Apply lubricating grease on movable parts at both ends of brush shaft.

Press carbon brush into its holder and install front cover of motor.

* Attentions

•

There should be no hurt on the contact

surface of carbon brush and armature. Take

care.

•

Installation shaft of armature cannot hurt

lip of oil seal. Take care.

电刷

电刷

KS MOTORCYCLES - http://ksmotorcycles.com