Page 6

Lift Terminology

regarding control switches and

their functions are provided in the

Lift Operation section.

Wireless Remote:

See Lift Op-

eration section.

Lift Housing:

The lift housing

is the metal structure (casing)

mounted under the vehicle which

contains and protects the platform

carriage assembly. The hous-

ing contains all lift components

except the power (pump) module

when the lift is in the stowed posi-

tion.

Platform Carriage Assembly:

The platform carriage assembly

includes the platform assembly,

the lifting arms, the rolling hori-

zontal arms that carry the plat-

form assembly in and out of the

housing and the electrical/hydrau-

lic drive components that power

the lift.

Platform Assembly:

The lift plat-

form assembly consists of the flat

aluminum plate upon which the

wheelchair is positioned, the outer

barrier, and the inboard locator.

Outer Barrier:

The spring-

loaded, electric actuator-driven

outer barrier provides a ramp for

wheelchair loading and unload-

ing at ground level. Photos and

further details are provided in the

Operation Notes and Details sec-

tion (pages 18-19).

Inboard Locator:

The

NUSP34S31X48RWO is

equipped with an automatic in-

board locator that also serves as

the bridge plate.

Lift Components

Refer to the Lift Terminology Il-

lustration on page 4.

Pump Module:

The remote

mounted pump module consists

of the main hydraulic pump, the

manual hand pump, the electronic

control board and other electrical

components that power the lift

electric/hydraulic systems.

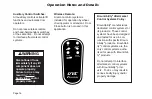

Hand-held Pendant Con-

trol:

The hand-held pendant is

equipped with three push button

switches, (STOW, DOWN and

UP). The momentary switches

activate the automatic lift func-

tions. Simply press the switch

labeled for the intended function.

The lift function labels illuminate

to identify the function(s). Details