Page 42

Maintenance and Lubrication Schedule

Perform all procedures listed in previous section also

1500

Cycles

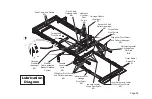

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Door Ease - See Lubrication Diagram. Apply

to the surface area around both slots and wipe off

excess.

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Synthetic Grease - See Lubrication Diagram

Use compressor and nozzle to remove all debris

from housing. Clean lower pan slot and apply

antiseize to slot before reinstalling pan.

Use clean cloth and solvent to clean tracks. Clean

outboard lower pan slot and apply antiseize to slot

before reinstalling pan.

Correct or replace damaged parts and/or relu-

bricate. See Drive Chain Adjustment in Service

Manual.

Carriage rollers (bearings)

Eccentric shaft rollers (bearings)

Rolling horizontal carriage arm slot area.

Hydraulic cylinder pivot points (4 per cylinder)

Drive chain and chain rollers

Drive chain release latch mechanism

Deploy lift, remove lower pan and blow out

housing. Blow off platform also.

Deploy lift, remove lower pan and clean

housing tracks

Check drive chain tensioner, jam nuts and

connecting link for securement and/or mis-

alignment.