Page 33

Decals and Antiskid

Decal Placement

Replace missing, worn

or illegible decals.

Failure to do so may

result in serious bodily

injury and/or property

damage.

WA

RNING

The lift is only as safe as

the operator. Replace any

missing, worn or illegible

decals! Part numbers are

provided for decals. In-

spect your lift for missing,

worn or illegible decals.

Call 1-800-946-7513

for

replacements.

Note: Clean surfaces as

detailed on page 36 before

posting decals.

NUVL603C-012(9-06).ai

WARN

ING

81823

Push

T-handl

e in ful

ly an

d

man

ually

mov

e plat

form in

and o

ut to

eng

age p

latfor

m

lock bef

ore dr

iving

vehic

le.

Failur

e to loc

k plat

form m

ay

resul

t in un

intend

ed pl

atfor

m

deplo

ymen

t. Un

intende

d

platfo

rm depl

oyment

may

resul

t in ser

ious

bod

ily inj

ury

and/o

r proper

ty dam

age.

Do not

remove

!

WARN

ING

81823

Push T

-hand

le in fu

lly and

manu

ally m

ove p

latform

in

and o

ut to e

ngage

platfo

rm

lock b

efore d

riving

vehic

le.

Failure

to loc

k platf

orm ma

y

result

in unin

tende

d platf

orm

deplo

ymen

t. Unin

tende

d

platfo

rm de

ploym

ent m

ay

result

in seri

ous b

odily in

jury

and/o

r prop

erty d

amag

e.

Do not

remove

!

STO

W

DO

WN

UP

214

94

LIFT

POW

ER

ON

OFF

OP

EN

CLO

S

E

WARNING

81823

Push T-handle in fully and

manually move platform in

and out to engage platform

lock before driving vehicle.

Failure to lock platform may

result in unintended platform

deployment. Unintended

platform deployment may

result in serious bodily injury

and/or property damage.

Do not remove!

UP

(TO

RA

ISE

PL

AT

FO

RM)

:

Us

ing

ha

nd

pum

p h

and

le:

1.

Clo

se

han

d p

um

p v

alv

e (t

urn

clo

ckw

ise

).

2.

Ins

ert

ha

ndl

e in

pu

mp

an

d s

tro

ke.

No

te:

Clo

se

val

ve b

efo

re

ope

rat

ing

ele

ctric

pum

p.

IN

(TO

ST

OW

PL

ATF

OR

M):

1.

Ra

ise

or

low

er p

latf

orm

to

sto

w

lev

el (

foll

ow

UP

or

DO

WN

pro

ced

ure

s).

2.

Pul

l T-

Ha

ndl

e.

3.

Tur

n T

-Ha

ndl

e to

loc

k p

latf

orm

in re

lea

sed

po

siti

on.

4.

Pu

sh

pla

tfor

m i

n.

5.

Tur

n T

-Ha

ndl

e.

6.

Pu

sh

T-H

and

le i

n.

7.

Tur

n T

-Han

dle

to

loc

k p

latf

orm

in e

nga

ged

po

siti

on.

Re

ad

ope

rat

or's

ma

nua

l for

fur

the

r de

tail

s.

DO

T —

Pub

lic

Us

e L

ift

314

09

MANUAL

OPERA

TION

OPE

N

CLO

S E

OP

EN

VAL

VE

CLO

SE

WARNING

81823

Push T-handle in fully and

manually move platform in

and out to engage platform

lock before driving vehicle.

Failure to lock platform may

result in unintended platform

deployment. Unintended

platform deployment may

result in serious bodily injury

and/or property damage.

Do not remove!

OU

TE

R B

AR

RIE

R

De

te

nt

Pi

n

PL

AT

FO

RM

Actuator

Hairpin

Cotter

OU

T (T

O E

XTE

ND

PLA

TFO

RM

):

1.

Pul

l T-

Handl

e.

2.

Tur

n T

-Ha

ndl

e to

loc

k p

latf

orm

in re

lea

sed

posi

tion

.

3.

Pul

l pl

atfor

m o

ut.

4.

Tur

n T

-Ha

ndl

e.

5.

Pus

h T

-Ha

ndl

e in

.

6.

Tur

n T

-Ha

ndl

e to

loc

k pl

atfo

rm

in e

nga

ged

po

siti

on.

DO

WN

(TO

LO

WE

R P

LATF

OR

M):

Usi

ng

han

d p

ump

ha

ndl

e, o

pen

hand

pu

mp

va

lve

(tur

n co

unt

er-

clo

ckw

ise

). O

pen

1/2

tur

n o

nly

.

DO

WN

(TO

UN

FO

LD

OU

TER

BA

RR

IER

):

1.

Rem

ove

ha

irpi

n c

otte

r

from

de

tent

pin.

2.

Rem

ove

de

tent

pin.

3.

Unf

old

(rot

ate

) barr

ier

dow

n.

UP

(TO

FO

LD

OU

TER

BA

RR

IER

):

1.

Fol

d (ro

tate

) ba

rrie

r up

.

2.

Ins

ert

det

ent

pin

.

3.

Inse

rt h

airp

in c

otte

r

in de

ten

t pi

n.

81

81

9

DA

NG

ER

KE

EP

CLE

AR O

F MOVI

NG

PAR

TS

818

19

DA

NG

ER

KEEP

CLEA

R O

F MOVI

NG

PARTS

WA

RN

ING

Face

ou

tward

an

d loc

k w

hee

lcha

ir

bra

kes b

efore

ope

ratin

g li

ft.

294

40

THIS WH

EELCHAIR L

IFT

CO

NFOR

MS

TO

THE

CALIFO

RNI

A

COD

E O

F REGU

LAT

ION

S

REQ

UIREMENTS

IN

EFF

ECT

ON

THE

DA

TE OF M

ANUF

ACT

URE

.

NU

VL

85

5R

e5

*7

2/

24

5*

95

/54

*0

10

2*

00

1-

800

-T

HE L

IF

T™

BR

AU

NL

IF

T.C

OM

™

Th

e B

ra

un C

or

po

ra

tio

n

DO

T

Pu

bli

c

U

se

Lif

t M

OD

EL

#

Max

. Lif

tin

g Ca

pa

cit

y -

75

0 l

bs.

U.

S.

P

ATE

NT

49

58

97

9

09/1

6/0

5

MF

G

DA

TE

01-000

25

SE

RI

AL

N

UM

BER

81

81

9

DA

NG

ER

KEE

P

CLEA

R OF M

OV

IN

G P

AR

TS

STO

W

DO

WN

UP

214

94

LIFT

PO

WE

R

ON

OFF

OP

EN

CLO

S

E

WARNING

81823

Push T-handle in fully and

manually move platform in

and out to engage platform

lock before driving vehicle.

Failure to lock platform may

result in unintended platform

deployment. Unintended

platform deployment may

result in serious bodily injury

and/or property damage.

Do not remove!

UP

(TO

RA

ISE

PLA

TFO

RM

):

Us

ing

han

d p

um

p ha

ndl

e:

1.

Clo

se

han

d p

um

p v

alv

e (t

urn

cloc

kw

ise

).

2.

Ins

ert

ha

ndl

e in

pum

p a

nd

str

oke

.

No

te: C

los

e v

alv

e b

efo

re

o

per

atin

g e

lec

tric p

um

p.

IN

(TO

ST

OW

PL

ATFO

RM

):

1.

Ra

ise

or

low

er p

latf

orm

to

stow

lev

el (

foll

ow

UP

or

DOW

N

proc

edu

res

).

2.

Pul

l T-

Ha

ndl

e.

3.

Turn

T-H

and

le t

o lo

ck

pla

tfo

rm

in re

lea

sed

pos

itio

n.

4.

Pu

sh

pla

tform

in.

5.

Tur

n T

-Han

dle

.

6.

Pus

h T

-Han

dle

in.

7.

Turn

T-H

andl

e to

loc

k p

latf

orm

in e

nga

ged

pos

itio

n.

Re

ad

ope

rat

or's

ma

nua

l fo

r fu

rthe

r d

eta

ils.

DO

T —

Pub

lic

Us

e Li

ft

314

09

MANUAL

OPERA

TION

OPE

N

CLO

S E

OPEN

VAL

VE

CLO

SE

WARNING

81823

Push T-handle in fully and

manually move platform in

and out to engage platform

lock before driving vehicle.

Failure to lock platform may

result in unintended platform

deployment. Unintended

platform deployment may

result in serious bodily injury

and/or property damage.

Do not remove!

OUT

ER

BAR

RIE

R

De

te

nt

Pi

n

PL

AT

FO

RM

Actuator

Hairpin

Cotter

OUT

(TO

EXTE

ND

PLA

TFOR

M):

1.

Pul

l T-Ha

ndl

e.

2.

Tur

n T

-Ha

ndl

e to

loc

k pl

atform

in re

lea

sed

pos

ition.

3.

Pul

l pl

atfo

rm

out

.

4.

Turn

T-H

andl

e.

5.

Push

T-Ha

ndl

e in.

6.

Tur

n T

-Ha

ndl

e to

lock

pla

tform

in e

nga

ged

pos

ition.

DO

WN

(TO

LOW

ER

PL

ATFOR

M):

Usi

ng

han

d pump

ha

ndl

e, ope

n

han

d pump

va

lve

(tur

n c

ount

er-

clock

wis

e).

Ope

n 1

/2 tu

rn onl

y.

DOWN

(TO

UN

FOL

D

OU

TER

BA

RR

IER

):

1.

Rem

ove

ha

irpi

n c

otte

r

from

dete

nt pi

n.

2.

Rem

ove

de

tent

pin.

3.

Unf

old

(rot

ate

) bar

rier

dow

n.

UP

(TO

FO

LD

OU

TER

BA

RR

IER

):

1.

Fol

d (r

ota

te)

barr

ier

up.

2.

Ins

ert

det

ent

pin

.

3.

Inse

rt hai

rpin

cot

ter

in de

tent

pin.

81

81

9

DA

NG

ER

KEEP

CL

EA

R O

F M

OV

ING P

ART

S

81819

DAN

GER

KEEP

CLEAR

OF MOVI

NG P

ART

S

WA

RN

ING

Face outwa

rd and lock whe

elch

air

brakes before o

perating lift.

818

14

THIS WH

EELCHAIR LIFT

CONFORMS T

O THE CAL

IFORNIA

CODE

OF REGULA

TIONS

REQUIREMENTS IN EFFECT ON

THE

DATE OF MAN

UFACTURE.

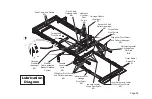

12377

81819

DAN

GE

R

KEEP

CLE

AR OF M

OVI

NG P

ARTS

81823

21494

30787

(not

visible)

28461

29884

81819

81819

29059

and

29060

29064

and

29065

406567 & 406568

(not visible)

29058

(not visible)

29055

(not visible)

18229

(not visible)

12377

81819

81814