SSB

6720892984 (2019/02) US

Service reminder | 59

Error no .

Error

Description

162

FLUE_BLOCKED

Flue is blocked, demand needs to be stopped with fan at ignition speed*, but

no error needed to be stored at this time

163

LOWEXFLOW_PROTECTION

Flow is too low, demand needs to be stopped with fan at ignition speed*, but no

error needed to be stored at this time

F .4

Warnings

Error no .

Error

Description

200

CC_LOSS_COMMUNICATION

Cascade System: Leading burner lost communication with one of the

depending burners.

201

CC_LOSS_BOILER_COMM

Cascade System: Leading boiler lost communication with one of the depending

boilers.

202

OUTDOOR_WRONG

Outdoor sensor is open of shorted

203

T_SYSTEM_WRONG

T_System sensor is open of shorted

204

T_CASCADE_WRONG

T_Cascade sensor is open of shorted

205

MAX_HIGH_LIMIT_WARNING

Too many physical high limit test attempts within 24 hours.

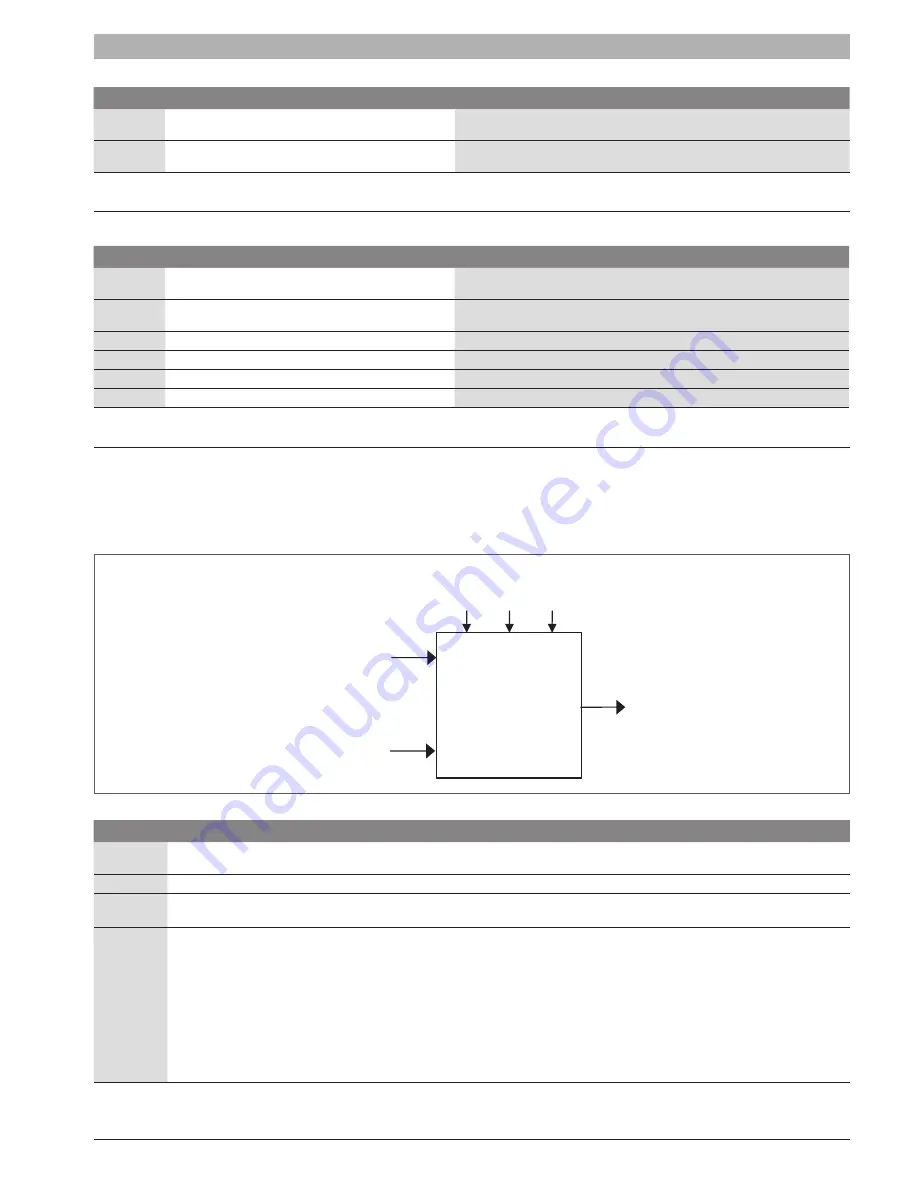

Appendix G - PID: Proportional-Integral-Derivative controller

For demand handling a software PID controller is implemented.

The PID controller calculates its output value as a function of the PID parameters, the setpoint and the input. The output can be used to control the fan for

regulation of power, or pump for controlling the flow, depending on the application.

Parameters used for the calculation are:

Input value

(sensor value, such as temp.)

Setpoint

Output value

PID

PARAMETERS

P I D

Input value

As input the parameter that needs to be controlled is given. In most cases this is a sensor temperature. This PID controller will then

control this input value to the given setpoint.

Setpoint

The setpoint value is the target value to which the input value is controlled to. This must be entered in the same format as the input value.

Output

The output is the target power to control the input value towards the setpoint.

The output value can be scaled between a minimum and maximum output so this can be used in a understandable format.

P

The P parameter of the PID-controller is used to adjust the speed of the regulation.

With a larger P-factor the regulation is faster, but it is more likely to create overshoot on the regulation.

The formula is P_Power = P * Error, where the error is the difference between the setpoint and the actual temperature in 1/32 degree

temperature steps. The P is a positive value when the difference (Setpoint > actual temperature) is also positive. This value is a part of the

output power.

The P is a negative value when the difference is also negative (Setpoint < actual temperature).

This means that this part of the output power is negative.

Summary of Contents for SSB1000 SA

Page 82: ...6720892984 2019 02 US SSB ...

Page 83: ...SSB 6720892984 2019 02 US ...