BRT7989/7200

Page 10

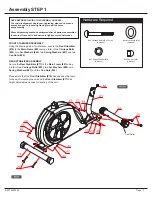

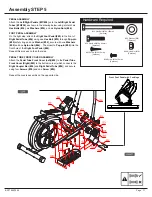

Assembly STEP 4

Hardware Required

COUPLER BAR ASSEMBLY (PART II)

Attach the

Right Pedal Tube (#04)

onto the

Crank (#21)

as

illustrated and secure by inserting from the outer edge of the

Right

Pedal Tube (#04)

, one

Pedal Hinge Bolt (#28)

and one

Wavy

Washer (#55)

. Secure from the inner edge (behind the

Crank(#21)

)

with one

Nylon Nut (#44)

.

*** PLEASE DO NOT tighten the hardware until steps below have

been completed. This will allow you to align the holes for proper

and smooth assembly.***

Repeat this process on the other side using the

Left Pedal Tube

(#03)

.

Using the drawings as a reference, attach the free end of the bottom

of the

Right Coupler Bar (#06)

to the front of the

Right Pedal Tube

(#04)

by aligning the holes. After the holes are aligned, insert one

Bolt

(#29)

through the

Right Pedal Tube (#04)

, the

Right Coupler Bar

(#06)

and secure using one

Washer (#51)

followed by one

Nylon Nut (#45)

.

Repeat this process on the other side using

Left Coupler Bar (#05)

and

Left Pedal Tube (#03)

.

***NOW, you may tighten the hardware on both sides.***

#28 Pedal Hinge Bolt (1/2" x 97mm)

[2 pieces]

#29 Bolt (M10 x 58mm)

[2 pieces]

#55 Wavy Washer (Ø16mm)

[2 pieces]

#51 Washer (M10)

[2 pieces]

#44 Nylon Nut (1/2")

[2 pieces]

#45 Nylon Nut (M10)

[2 pieces]