10

Electrical Assembly - Vehicle Harness

Electrical Assembly - Vehicle Harness

CAUTION: Always perform the vehicle wire harness assem-

bly with the vehicle off and the keys out of the ignition. Use

caution when testing the electrical wires for the vehicle’s

headlight functions.

1.

Begin the installation of the electrical harness under the hood. Insert

the WHITE POWER CONNECTOR & RED POWER WIRE (with FUSE)

end of the harness through the driver’s side fire wall access panel into

the vehicle cab. Note:You may need to widen an opening or cut access

to the cab interior to facilitate the assembly. Loosely position the

remaining portion of the harness over the driver’s side fender well and

place the MOLDED RUBBER POWER CONNECTOR near the bumper.

Note: Keep the plow and vehicle rubber power connector pins lubri-

cated with a liberal amount of dielectric grease. Always replace the

protective RUBBER WEATHER CAPS when the plow is disconnected

from the vehicle.

2.

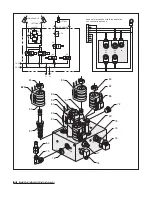

Next, attach the POWER CONTACTOR (SOLENOID) to the driver’s

side wheel well or engine fan guard using two 12-14 x 3/4" hex washer

self-drilling screws. Note: Some model vehicles provide mounting

locations for accessory components. Always mount the solenoid with

the terminals facing up. This will extend the useful life of the solenoid.

Connect the 24" BLACK GROUND WIRE to either small terminal on

the solenoid and attach the opposite end to the vehicle with one hex

washer self-drilling screw. Locate the BROWN/WHITE PUMP SOLE-

NOID ACTIVATION WIRE on the wire harness and position the eyelet

over the remaining small terminal on the contactor. Secure it with the

hardware provided on the solenoid.

3.

Proceed to connect the BLACK VEHICLE WIRE HARNESS GROUND

WIRE to the negative terminal on the vehicle’s battery. Cut the wire to

length and crimp a 3/8" DIA. END RING TERMINAL on the wire. It is

also recommended that the ring terminal be soldered. Note: The har-

ness should be secured to the vehicle prior to taking the necessary

measurement. Measure the distance needed for the RED POWER

WIRE to reach the solenoid and properly secure an end ring terminal

to it. Connect the power wire to either large terminal on the solenoid.

CAUTION: Do not fasten the wire harness to areas that come

in contact with moving engine parts or possess extreme

heat.The harness could become tangled and/or melt causing

electrical failure and vehicle damage.

4.

Attach and solder an end ring terminal to both ends of the remaining

length of the red 4 gauge wire. Connect one end of the wire to the

open terminal on the solenoid and the remaining end to the positive

terminal on the battery.

5.

With the vehicle harness secured to the truck, position the MAIN

LIGHTING HARNESS such that both of the large, gray VEHICLE

HEADLIGHT CONNECTORS are near the truck headlights and the

smaller, black PLOW HEADLIGHT CONNECTORS are near the grill

of the vehicle.

A

B

C

D

Heavy-Duty Power Contactor (Solenoid)

There are four wires that need to be attached to

the power contactor:

(A) Red Power Battery Wire

(B) Vehicle Wire Harness Red Power Wire

(C) 24" Black Ground Wire

(D) Brown/White Pump Solenoid Activation Wire

Summary of Contents for 680LT

Page 17: ...Notes 15 Notes...