BestCode Next Series 8 Technical Manual

October 2022

Page 91 of 290

6.

Remove the Solvent Filter and

discard in accordance with local

regulations.

7.

Install new Solvent Filter.

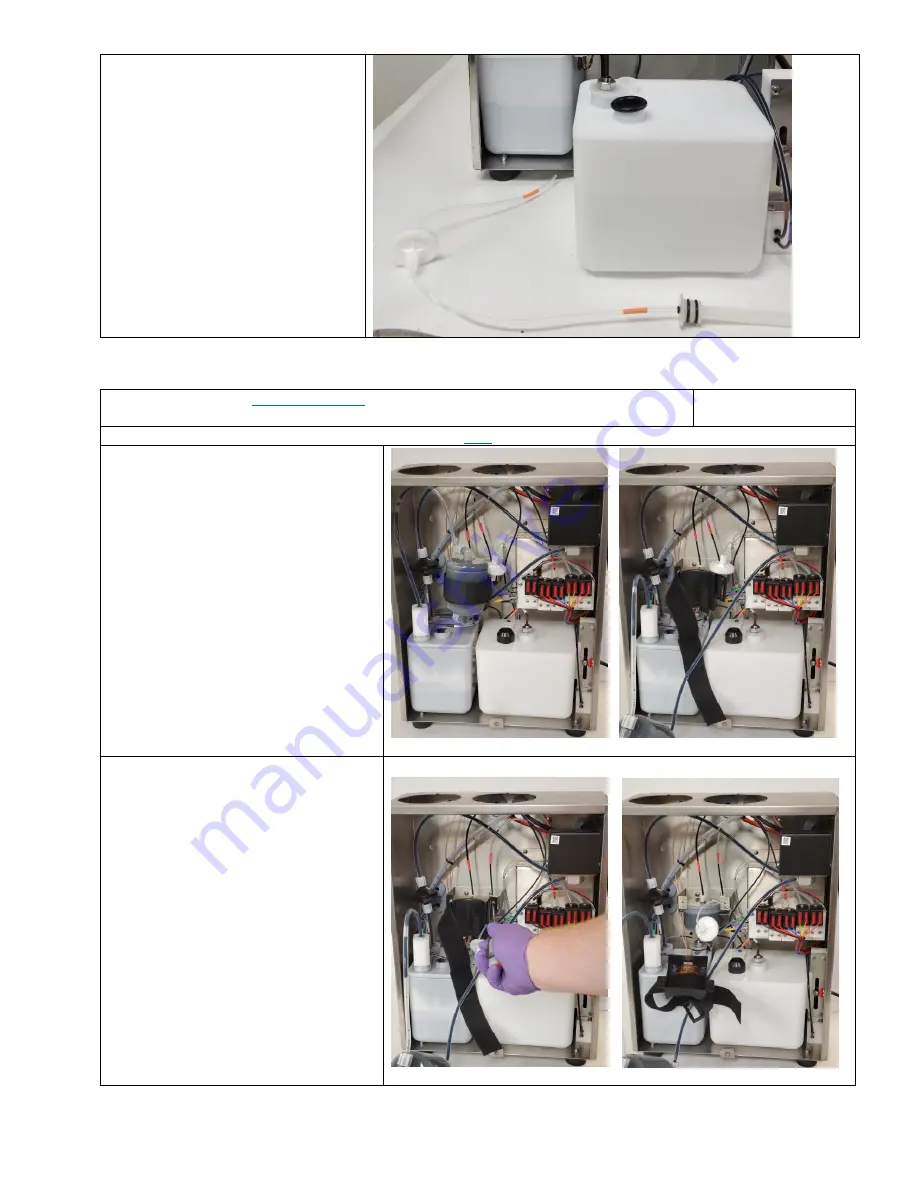

Dampener Printhead Assembly (31-0054-01) Replacement

Be familiar with proper

Procedure Time: 15

minutes

1.

Remove the Ink & Makeup SmartFill cup Instructions

2.

Remove the Main Ink Filter from the

Filter Housing

3.

Remove the SmartFilter Housing by

removed the 2 M4 screws from the

SmartFilter bracket

4.

Locate the Dampener Printhead

Assembly (31-0054-01)

Summary of Contents for Next 8 Series

Page 2: ......

Page 3: ......

Page 4: ......

Page 143: ...BestCode Next Series 8 Technical Manual October 2022 Page 129 of 290 USB ...

Page 144: ...BestCode Next Series 8 Technical Manual October 2022 Page 130 of 290 Collector Information ...

Page 259: ...BestCode Next Series 8 Technical Manual October 2022 Page 245 of 290 ...

Page 264: ...BestCode Next Series 8 Technical Manual October 2022 Page 250 of 290 ...

Page 268: ...BestCode Next Series 8 Technical Manual October 2022 Page 254 of 290 ...

Page 276: ...BestCode Next Series 8 Technical Manual October 2022 Page 262 of 290 Using the Molex Crimper ...

Page 277: ...BestCode Next Series 8 Technical Manual October 2022 Page 263 of 290 ...