Operation METPOINT® BDL compact

METPOINT® BDL compact

71

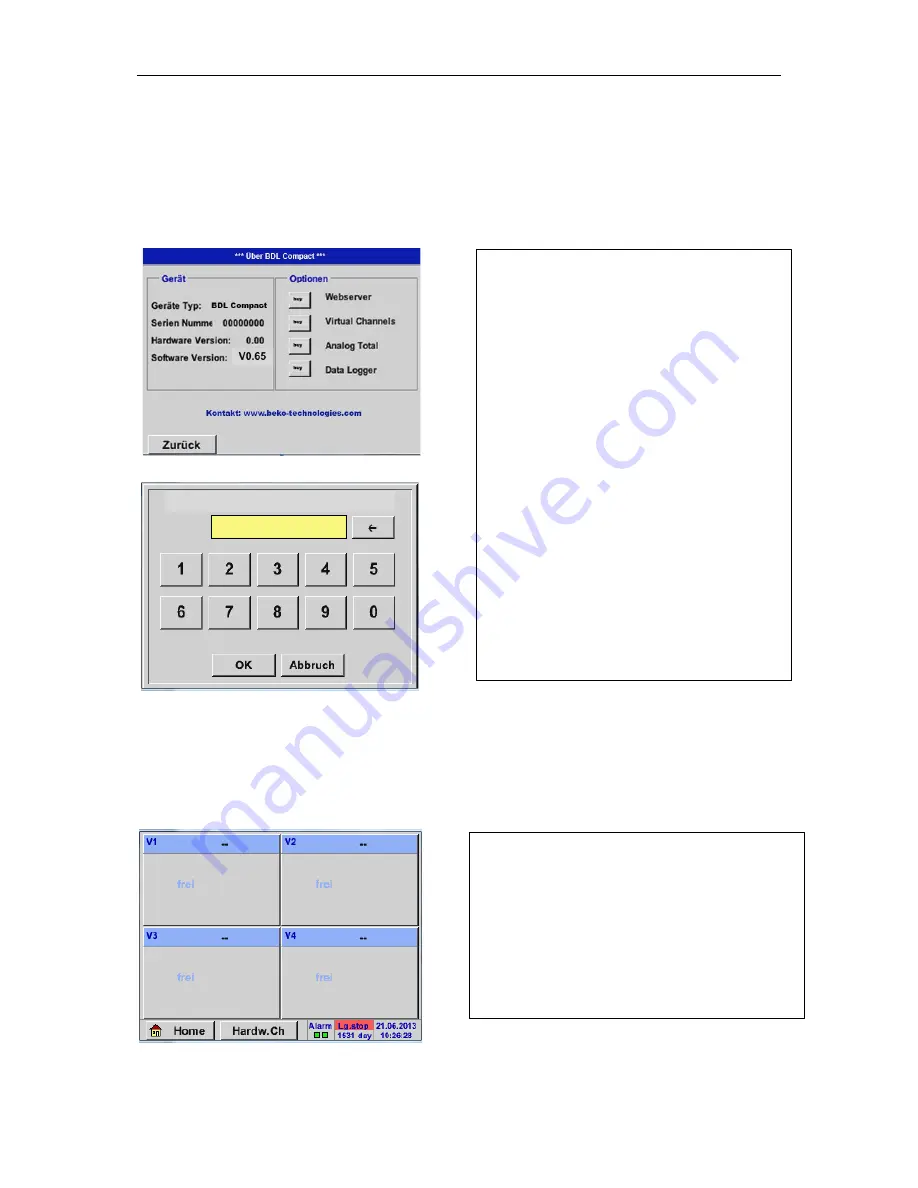

14.3.8.1 Activate the option "virtual channels"

After having acquired the "virtual channels" option, the latter needs to be activated first.

Main menu

Settings

Via METPOINT

®

BDL compact

Enter Code für Option 2

14.3.8.2 Virtual channels settings

Main menu

Settings

Sensor settings

Virtual channels

D By pressing the

Buy

button for "virtual chan-

nels", you will be requested to enter the activa-

tion code.

Please enter your activation code into the text

field and activate it by pressing the

OK

button.

After having activated the "virtual channels" but-

ton in the sensor setting menu, an overview of the

available four channels will appear.

Note:

Channels are not preset as a standard.

Summary of Contents for METPOINT BDL compact

Page 15: ...Dimensions METPOINT BDL compact 15 Cutout for the mounting of the instrument panel ...

Page 83: ...Operation METPOINT BDL compact METPOINT BDL compact 83 Info Status ...

Page 84: ...Operation METPOINT BDL compact 84 METPOINT BDL compact Actual Values ...

Page 102: ...Declaration of conformity 102 METPOINT BDL compact 18 Declaration of conformity ...

Page 105: ...METPOINT BDL compact 105 ...

Page 106: ...METPOINT BDL compact ...

Page 107: ...METPOINT BDL compact 107 ...