7

4. SYSTEM DESIGN FOR HAZARDOUS

AREAS

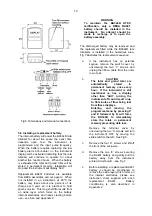

When mounted in a hazardous area the

BA344D can operate as a stand alone rate

totaliser without the need for Zener barriers or

galvanic isolators as shown in Fig 2.

Fig 2 Stand alone operation within hazardous

area

The voltage pulse input terminals 3 and 4 may

be directly connected to any certified

intrinsically safe voltage source within the

hazardous area which can withstand a 500V

rms insulation test to earth for one minute and

has output parameters equal to or less than:

Uo

=

28V dc

Io

=

100mA dc

Po

=

0.7W

This enables the BA344D to be connected

directly to most flowmeters incorporating a

certified intrinsically safe magnetic pick-off, or

a certified intrinsically safe amplifier producing

a high level pulse output. The maximum input

counting frequency is 10kHz.

Any mechanically activated switch contact

located in the hazardous area may be directly

connected to terminals 5 & 6 providing the

switch and associated wiring have IP20

protection and can withstand a 500V rms

insulation test to earth for one minute. This

allows most magnetically activated reed relays

used in turbine flowmeters to be directly

connected to terminals 5 & 6. The BA344D

contains filtering to prevent contact bounce

being counted which limits the maximum

operating frequency for a switch contact to

100Hz.

Similarly, an open collector transistor with

certified segregation, such as those used in

intrinsically safe opto-isolators may be directly

connected to terminals 5 & 6. The maximum

input counting frequency is 10kHz.

4.1 System certificates

When the input signal is derived from the safe

area or the total display is to be reset from

within the safe area, Zener barriers or galvanic

isolators are required to transfer the signals in

and out of the hazardous area.

In addition to the ATEX EC-Type Examination

Certificate, ITS have issued two system

certificates. One defines how the BA344D may

be used with Zener barriers and the other with

galvanic isolators. Both are divided into two

sections to cover input signal sources in the

hazardous and in the safe area.

Interface Certificate No

Zener barriers

Ex01E2018

Galvanic isolators

Ex01E2019

This section interprets these system

certificates and illustrates how to design

systems with Zener barriers and galvanic

isolators.

System certificates are Certificates of

Conformity which are primarily issued for

guidance in the UK. They do not form part of

certification to the European ATEX Directive.

4.2 Use with Zener barriers

Zener barriers are the least expensive

intrinsically safe interface between a safe and

hazardous area. However they do not provide

isolation and require a high integrity earth

connection that may be expensive to install.

For a single BA344D it may be less expensive

and complicated to use galvanic isolators when

a high integrity earth connection is not already

available.

Any certified Zener barriers may be used with

the BA344D providing their output parameters

do not exceed the input parameters of the

terminals to which they are connected. Only

one polarity of Zener barrier i.e. positive or

negative , may be used with each instrument.

Summary of Contents for BA344D

Page 13: ...13...