17

display stability. The second digit should then

be increased until the selected step size is

greater than the noise on the display signal, at

which setting the rate display will again

become stable. These will be the optimum

filter parameters for acceptable rate display

stability and a fast response to a large rate

signal change.

To check or change the filter select 'FILtEr'

from the main menu and press

P

to reveal the

current settings. Pressing the

Up

or

Down

button will change the flashing digit and

P

will

transfer control to the second digit. While

making adjustments the filtered rate display is

shown on the lower display so that stability can

be assessed. When set as required, press the

E

button to enter the revised parameters and

return to the main menu.

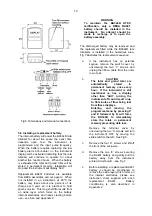

6.11 Total scale factor: ‘SCALE-t’

This factor defines the arithmetic relationship

between the number of input pulses and the

total display. SCALE-t is a dividing factor that

may be adjusted between 0.001 and

99999999. See Fig 8.

When used with a flowmeter SCALE-t should

be set to the K-factor of the flowmeter i.e. the

number of pulses the flowmeter produces for a

unit of flow. If the BA344D total display is

required in units different from those in which

the flowmeter K factor is specified, a

conversion factor will be required.

e.g. If the flowmeter has a K factor of 45.6

pulses per litre and the BA344D total display is

required in units of 1,000 gallons, then

SCALE-t should be set to number of pulses

produced by the flowmeter per 1,000 gallons:

45.6 x 4.54609 x 1000

207,301.7 pulses per 1000 gallons

.

(there are 4.54609 litres in a UK gallon)

To check or change the total scale factor select

'SCALE-t' from the main menu and press

P

to

reveal the existing setting, one digit will be

flashing. The value of the flashing digit can be

changed by pressing the

Up

or

Down

buttons.

When this digit is correct pressing

P

will

transfer control to the next digit.

To position the decimal point in the scale

factor, move the flashing digit to the left hand

side of the required decimal point position and

simultaneously press the

Up

and

Down

buttons.

When the required total scale factor has been

entered, press

E t

o store the number and

return to the main menu.

Note:

After changing the total scale factor, the

total and grand total will be reset to zero

6.12 Clip-off: ‘CLIP-OFF’

To prevent totalisation of very low flow rates

which over long periods may result in

significant totalisation errors, the BA344D may

be programmed to stop totalising when the flow

rate falls below an adjustable threshold.

To check or change the clip-off threshold select

'CLIP-OFF' from the main menu and press

P

which will reveal the current setting. The

threshold is shown in units of flow rate with one

digit flashing. The value of the flashing digit

may be changed by pressing the

Up

or

Down

buttons. When this digit is correct pressing

P

will transfer control to the next digit. When set

as required, press the

E

button to enter the

revised figure and return to the main

programme menu.

If the flow rate falls below the entered

threshold, the rate display will show zero flow,

totalisation will stop and the HOLD annunciator

will be activated. The flow indicator will

continue to rotate as defined in section 2.2

Note:

When the rate scale factor SCALE-r, the

timebase t-bASE, or the position of the rate

display decimal point are changed, clip-off will

automatically be reset to zero. If required, a

new clip-off threshold may then be entered.

6.13 Local reset of total display:

‘LOC. rSEt’

When activated this function enables the

operator to reset the BA344D total display to

zero in the display mode by operating the

Up

and

Down

push-buttons simultaneously for two

seconds. To check the status of the local

reset function select 'LOC.rSEt' from the menu

and press

P

which will reveal if the function is

'On' or 'OFF'. If necessary press the

Up

or

Down

button to change the setting, followed by

the

E

button to return to the main menu.

The total display may also be reset to zero

remotely by connecting terminals 7 and 8

together. See section 3.4 of this manual.

Summary of Contents for BA344D

Page 13: ...13...