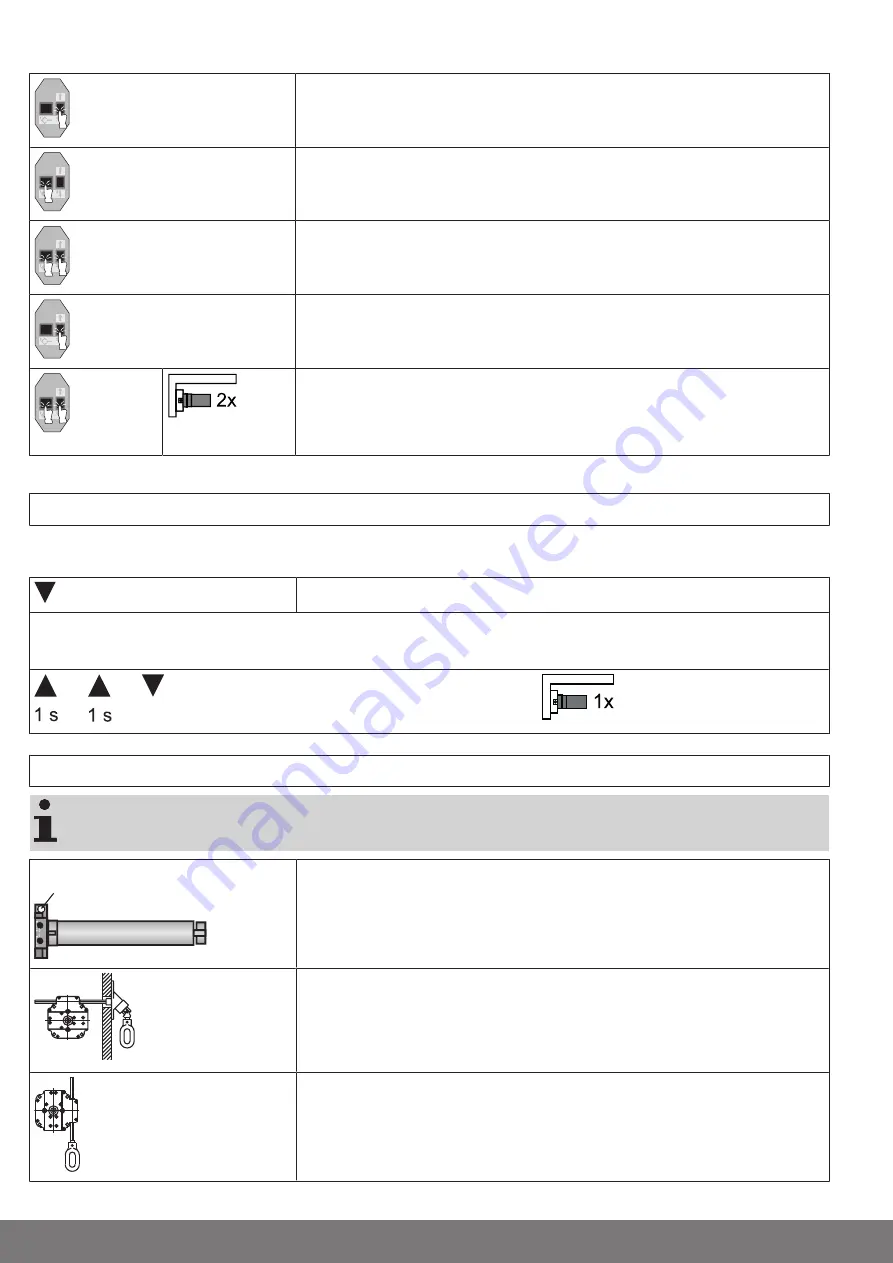

Deleting both limit positions

Open/close the shading solution to a point between the limit positions.

Press the programming button and keep it pressed.

Then press down the travel button and keep it pressed.

Now release the programming button, but continue to keep the travel button pressed.

Next press the programming button again.

▻

The tubular drive acknowledges.

►

Both limit positions are deleted.

Additional function offset lower limit position

The lower limit position can be advanced in 20° steps up to 60°. After 60° the forward displacement starts again at 0°.

Proceed as follows:

Move to the lower limit position.

Carry out the following sequence without interruption between the individual drive commands.

▻

The tubular drive confirms.

until STOP and hold until

Using the crank handle

For problem-free assembly, use mechanical and electrical accessories made by the drive

manufacturer which have been tested and which are suitable for use with these drives.

For 7 mm hexagonal tube

and 8 mm square tube

The crank handle is to be used only in the event of a power failure. It must be ensured

that the limit positions are not overrun. After using the crank handle, the limit posi-

tions must be referenced again. To do this, move in the opposite direction to the

per-

manent stop

to reference the limit positions again.

Crank handle for closed models

The crank handle for closed models can be used with roller shutters either with or

without a roll-up system. The square bar is fixed to the shutter box. Here, it is import-

ant to ensure that the bar is mounted parallel to the guide in the crank handle hous-

ing.

Crank handle for open models

These crank handles can be used with roller shutters without roll-up systems. Insert

the square bar into the guide in the crank handle housing and secure axially using a

retaining washer or two set screws.

14 - en