BDDF00122 Issue 3

16/36

Alaris™ Gateway Workstation v1.3.x

Features of the Workstation

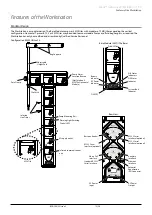

Adjustable Height Bag Hangers (where fitted)

The 18 mm diameter adjustable height pole has been designed as a convenient means of securing the fluid bags onto the Workstation .

The pole supports a maximum load to 3 kg . The pole is held securely by a clamp and a slip catch . This gives additional flexibility when

selecting the required height of the fluid bags . To operate the clamp:

1 . Grip the handle at the lower end of the pole and carefully loosen the hand wheel .

3b

1

2

4

3

2 . Apply an upward pressure to the pole handle, this will release the locking lever and allow

the pole to move freely .

3 . Changing the bag hanger height:

a) To increase the bag hanger height: Continue pushing the pole upward to the required

height . Once set, release the upward pressure on the pole, re-engaging the locking lever .

b) To reduce the bag hanger height: Hold the locking lever in the released position and

adjust the pole downward to the required height . Release the locking lever and release

the upward pressure on the pole, re-engaging the locking lever .

4 . Tighten the hand wheel to securely lock the pole into position .

To reduce the potential risk for nuisance alarms, the fluid bag should be placed at the height recommended in the

specific Pump Directions For Use, bag hanger poles should be adjusted to the required height.

For Workstation configurations 80300UNSxx-235 and 80300UNSxx-035, use the bag hanger assembly PN 1000SP01414

to secure fluid bags onto the Workstation.

Power Input

The Workstation is powered from the AC supply through a standard IEC AC connector . When connected to the AC supply the AC Power

indicator is illuminated . Both the Live and Neutral lines of the main supply are protected using fuses carried in a double fuse holder

located on the AC inlet connector .

Warning: When connected to the AC supply, a three wire (Live, Neutral, Earth) supply must be used. If the integrity of the

external protective conductor in the installation or its arrangement is in doubt, then the Workstation must not be

used.

To isolate the Workstation from AC supply remove the AC connector from the source socket. The Workstation should

be positioned to allow access for disconnecting the AC connector.

Battery Supply

The Workstation should normally be operated from the AC power supply . However, in the event of temporary loss of AC power, an

internal power supply will provide 60 minutes of communications . AC power to the Pumps will be discontinued .

Warning: AC Power should be re-applied as soon as possible as there will be no AC power supplied to the Pumps while the

Workstation is running on the battery.

The Battery indicator illuminates whenever the Workstation is running from the internal battery . When illuminated the Workstation is

operating from internal battery; when flashing the battery power is low and auto power down is imminent . The battery is automatically

charged whenever the Workstation is connected to the AC supply . As the Workstation is designed to operate from the AC power supply it

will only power up when connected to the AC supply .

Caution: In the event of a power loss, the Workstation with fully charged battery will emit an audible tone every 30 seconds

for the first 14 minutes to alert operators, accompanied by a visual indicator. This audible tone and visual indicator

will escalate to every 15 seconds after 14 minutes until the battery is fully depleted. These tones and indications

should not be confused with the continuous alarm and LED notification that is initiated if the Workstation exhibits a

fault condition.

If transfer of the Workstation is required, then prior to disconnecting from AC power supply the User must ensure

there is sufficient battery power on each of the Pumps.