28

11 – Take the control panel and the top front panel

of the casing.

Boilers with basic control panel one

stage

11.1 – Fix the control panel (29) to the panel (30)

with the four screws supplied.

Straighten up the capillary tubes of the

thermostats and thermometer (31),

introduce the bulbs in the pocket (9) and

fix them with the incorporated clip.

Straighten up the capillary tube of the

pressure gauge (32) and fasten it to the

check valve (12). See Fig. 13.

Pass the electrical cables through the

cable entry (33) and wire the thermostats

to the control panel (29) in accordance

with the directions in the instructions for

the burner.

The door switch (7) must be connected in

series with the limit thermostat (35). See

Fig.4.

Boilers with basic control panel two

stages or digital KSF panel

11.1 – Open the control panel to gain access

to the terminal strip and to the capillary

tubes of the thermostats, thermometer

and pressure gauge.

Straighten the capillary tubes, passing

them across the base of the control panel

and through the knockouts in the top front

panel of the outer casing.

Fasten the base of the control station to

the panel with the screws provided.

In those models with a 2 stage basic control

panel (38 Fig.4) the thermostat bulbs

(39) and the bulb of the combined temp./

altitude gauge (40) will be introduced in

the pocket (9, fig. 14). The pocket located

in the socket (10, fig. 9) of the heating

flow pipe (11, fig. 9). Introduce and fix the

pressure sensor of the combined temp./

altitude gauge in the check valve (12)

located in the connection (13).

In those models equipped with KSF control

panel (70 Fig. 4), the safety thermostat

bulb (39 Fig 14a) and the temperature

sensor (78) will be introduced in the

pocked as showed on Fig. 14a, using the

spring (79) supplied with the KSF control

panel. Introduce and fix the pocket (9

Fig. 14a) in the socket (10 Fig. 9) of the

heating flow pipe (11, fig. 9).

It is recommended that heat conducting

paste be put in the pocket beforehand.

Fix the bulbs into the pockits using the

incorporated clips.

12 – Assemble the sides of the casing which

for the moment will be suspended by the

slots in the front (41) and rear (42) tubular

plates. See Fig. 15.

13 – Put the top central panel in place and by

simple pressure it will remain fixed to the

side panels.

14 – Put in place the top front and rear panels

which will rest on the central cover and will

remain fixed by the side clips.

15 – Open the boiler door and check the correct

position of the turbulators (43), which

should be level with the tubes at the front

of the boiler. Both sections should be

interconnected; should they have become

separated, pull the long section out a little,

give a quarter turn to the short section and

interconnect them again.

From the CPA 345-BT upwards, each

turbulator consists of two sections: a long

one which should remain in the final part of

the tube and a shorter one of stainless steel

which should be level with the tube at the

front of the boiler.

16 – Assemble the burner on the boiler door. If the

burner is not made by

BAXI , you should

check that the flame tube (44) surpasses the

ceramic fibre (45) by at least 20 mm. See Fig. 16.

Important:

Fill with rock wool or ceramic fibre (45) Fig. 16

the space which might remain between the flame

tube (44) and the insulating fibre (45) of the door.

17 – Make the fuel connection to the burner.

18 – Electrical connection

The installation should include a circuit

breaker or other omnipolar disconnect switch

to isolate all power supply to the boiler.

The connection of external appliances should

be done through approved wiring harness

type ES-NOSW5-F.

Basic control panel (one stage

operation)

The electrical connection between the burner

and the boiler thermostats will be carried out in

accordance with the instructions for the burner.

The door switch will be connected in series with

the limit thermostat.

Basic control panel (two stage

operation)

Control panel supply voltage: 220/230 V~, 50 Hz.

The components which can be connected to the

control panel and their maximum power input are

the following:

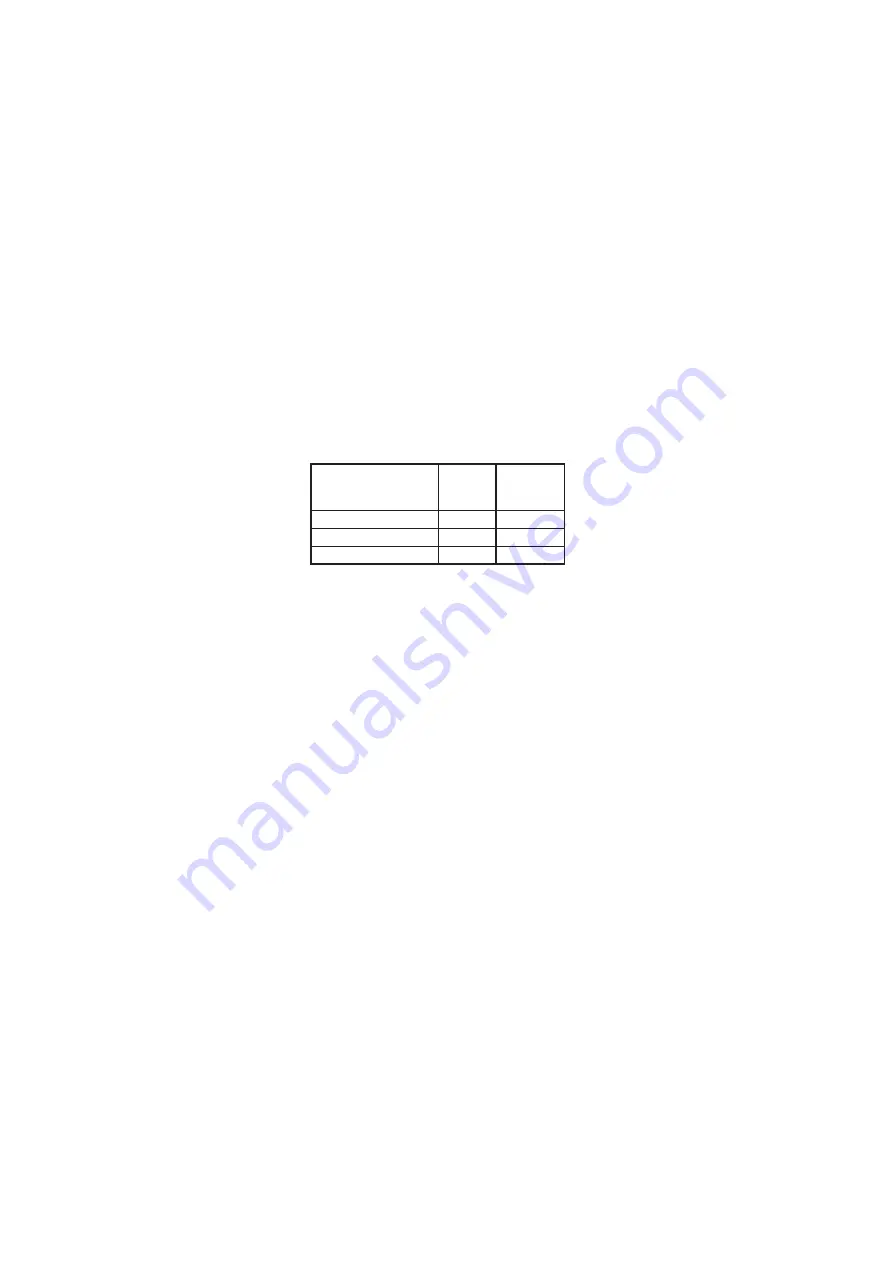

Component

Control

Panel

Terminal

Max.

power

Input

Pump

5-6

1000 W

Burner

14-6

1000 W

Storage cylinder

4-7

2800 W

However, the total electrical load of components

must not exceed 2,800 W.

KSF digital control panel

In the manuals of the KSF panel (70 Fig.4), you

will find a complete information about features and

heating installations can be managed with this

panel, which has specific components like fuse

(72), overtemperature lookout indicator (71) and

the control unit with LCD screen (73).

Electrical Connection Between the

Control Panel and Burner

See fig. 17 to 23

See legend in fig. 20

Electrical components of the Gas Train must be

connected according to burner instructions.

Legend. See Fig. 19.

19 – Burners with an air pressure test point (47)

Fig. 24 will have to be connected to the

boiler pressure test point (55) using a flexible

silicone hose (56). The pressure test point

screw should be removed before-hand.

20 – Check that there is no foreign body in the

combustion chamber. Fix the inspection

window assembly on the door (57). Fig. 24.

21 – Proceed to start up and adjust the burner,

making sure that all valves are open and that

the pump operates correctly.

22 – Start up the boiler and check for leak

tightness of flue gases with the burner at

full output. Should leak tightness not be

complete, re-tighten the nut or door clamp

nearest to the zone where the gases escape.

Having achieved complete gas-tightness,

tighten all the backnuts (6) on the hinge

side, one against the door (48) and the other

against the hinge (49). Fig.6. Do the same on

the side of the clamps, remembering, once

tightened (2) to lock the position with the

existing Allen screw (50) Fig.25.

23 – Immediately after proceed to assemble the

door casing. First open the door by undoing

the clamps. Then unscrew the arms of the

clamps.

CPA 55-BT to CPA 230-BT boilers

23.1 – Remove the burner temporarily without

needing to disconnect the oil and electricity

supplies.

23.2 – Undo the inspection window assembly.

Position the casing on the door and fix it

to this with the four screws supplied (51).

Fig. 26.

23.3 – Replace the arms of the clamps and the

inspection window assembly.

23.4 – Replace and fix the burner on the door.

CPA 290-BT to CPA 1740-BT boilers

23.1 – The door casing is supplied in two parts. To

assemble them, a light pressure is enough

for the upper (52) Fig. 26 and lower pins to

enter the housing clip. It is not necessary

to remove the burner.

23.2 – Join the two parts of the casing with the

upper screws (53) and the two lower screws

(54) provided. Position the casing on the

door and fix it to this with the four screws

(51) provided.

23.3 – Replace the arms of the door clamps.

Operation

Checks and steps to follow for starting up the

boiler and the installation.

Preliminary operations

– Check that the installation is full of water, vented

and a pressure of 0,5 bar above the static head

of the installation, at least.

– Start up the pump or pumps. Check that they

are turning.

– Bleed the air from the installation and radiators.

– In sealed & pressurised systems, refill with

water until the adjustable pointer is slightly

above the position of the fixed one.

– Close the boiler door, tightening it with the

clamps until they come up against the backnuts

(2) incorporated.

First lighting

– Follow the instructions which are supplied with

the burner.

– Set the control thermostat (34) Fig. 4 to

about 80 °C and check that this and the limit

thermostat operate correctly.

– The two stage basic control panel (38), is

prepared for controlling the burner in two stages,

and therefore incorporates two control thermos-

tats (34) Fig. 4. The thermostat regulated to

lower temperatures controls the second stage,

whilst the other, which is regulated to higher

temperatures, controls the first stage.

– Vent the installation again and check that the

radiators warm up satisfactorily.

Important recommendations

– If there is danger of freezing, add some anti-

freeze product to the water.

– Keep the same amount of water in the system

at all times; water should only be added when

topping up is absolutely necessary.

– Uncontrolled topping up with water may cause

limescale deposits in the boiler, damage it

seriously and reduce its performance.

– We recommend that the properties of the water

in the system be:

pH between

7.5 and 8.5.

Hardness:

8 to 12 French degrees (*).

(*) One French degree is equivalent to 1 gram of

calcium carbonate per 100 litres of water.

– Any work on the boiler or the installation must

be performed by qualified personnel.

Summary of Contents for CPA 1045-BT

Page 33: ...33...