Operation and Maintenance Manual

495B ML TM (S)

65

Last Updated - 08/31/2016

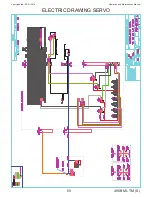

ELECTRIC COLLECTOR MAINTENANCE

COLLECTOR DESCRIPTION

The electric collector is designed for maximum efficiency with a minimum of maintenance. Located at the center of

rotation, collector rings (on the core assembly) maintain full electrical contact at all times between a rotating member

with continuous (360 degree) rotation and a stationary member. Without the collector, the wire harness would twist off

and electrical contact would be lost.

On all circuits from 10 to 30 amp capacity, the brushes ride on a 3/16" wide brass ring.

One brush pair per circuit is used on 10 to 20 amp circuits.

Two brush pairs per circuit are used on 30 amp circuits.

On circuits with 45 and 75 amp capacity, the brushes ride on a 3/8" wide brass ring.

A single pair of wide brushes is used on 45 amp circuits.

Two pair of wide brushes are used on 75 amp circuits.

On circuits with special 7.5 amp capacity, the brushes ride on a 3/32" brass ring.

Brushes are fastened to the brush arms to allow pivoting of the brushes. This assures complete contact at all times

between the brush and the brass ring, and is especially important if an orbiting condition develops as the equipment

ages.

COLLECTOR MAINTENANCE

Under normal operating conditions, the self-cleaning brushes will last the life of the equipment. However, if the

collector is not revolved for some time, it will collect fine silt (or, in a salt atmosphere, corrosion may result). If this

happens, the equipment should be rotated through several revolutions if possible. The cleaning action of the brushes

should clean the ring surfaces. If it does not, or if it is not practical to revolve the machine, it may be necessary to

use a standard non-residue solvent to clean the rings. Then lightly sand the brushes and rings with a fine grade of

sandpaper and dust off with compressed air.

The brush assemblies can be replaced if needed. See Brush Assembly Replacement.

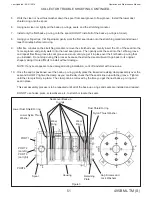

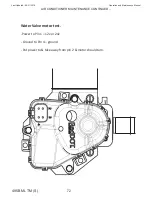

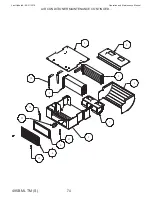

Knife Disconnect Terminals

with Plastic Sleeves

Mounting Tube

(fastened to stationary

member of machine)

Brush Harness

Center Harness

Set Collar (socket screw-type)

Cap Screw

Cover

Outboard Bearing (nylon)

Base Bracket

Brush Holding Stud

Base Bracket Connector

Brush/Arm/Spring Assemblies

Acorn Nut

Hex Lock Nuts

Nylon Rub Disk

Set Screw-Type Connectors

Jam Nuts

Nylon Bearing

Core Assembly (has brass rings that brushes

ride on)

Summary of Contents for 495B SD

Page 3: ...Introduction...

Page 7: ......

Page 16: ...Maintenance...

Page 19: ...Operation and Maintenance Manual 495B ML TM S 19 Last Updated 08 31 2016 SERVICE SCHEDULE...

Page 29: ...Hydraulic...

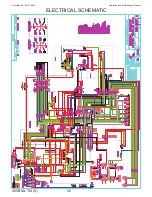

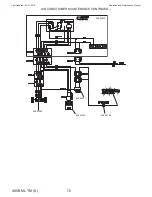

Page 57: ...Electrical...

Page 58: ...Operation and Maintenance Manual Last Updated 08 31 2016 495B ML TM S 58 ELECTRICAL SCHEMATIC...

Page 78: ...Maintenance...

Page 88: ...Operation and Maintenance Manual Last Updated 08 31 2016 495B ML TM S 88 Structural...

Page 95: ...Trouble Shooting...