Operation and Maintenance Manual

495B ML TM (S)

49

Last Updated - 08/31/2016

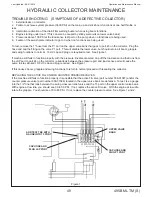

TROUBLE SHOOTING

1. External leaks on collector.

2. Failure to achieve system pressure (3600 PSI) on the main up and stick boom functions at one half throttle or

less.

3. Intermittent activation of the drain filter warning buzzer when using boom functions.

4. Engine starting under load. (This can also be caused by sticky solenoids on lower valve bank).

5. Pressures above 100 PSI at the load sense test port on the pump when no functions are being used.

6. Failure of the swash plate indicator to go to 0 when no functions are being used.

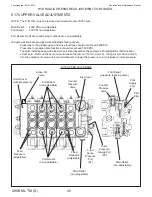

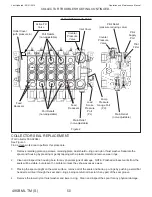

To test, remove the 1" hose from the P1 port on the upper valve bank that goes to port #3 on the collector. Plug the

hose and cap the fitting on the valve P1 port. This will disable the lower valve, but should return all boom, grapple

and swing functions to normal. 16 JIC cap and plug are required to test. See Figure 1.

If machine still fails to function properly with the pressure line disconnected, cap off the load sense line that runs from

the LSP port to port #4 on the collector (a seal leak between the pressure port and load sense port will cause the

pump to stay stroked). 3/8 JIC cap and plug required. See Figure 1.

If this causes boom, grapple and swing functions to return to normal proceed with resealing the collector.

REPLACING THE ACTIVE FILL AND/OR COUNTER PRESSURE VALVES

If the machine still fails to function properly it is possible that the active fill valve (part number 558-01587) and/or the

counter pressure valve (part number 558-01586) located in the upper valve bank are defective. To test, tee a gauge

into the 1/2" line that runs between the swing crossover relief valve and the T3 port on the upper control valve bank.

With engine at low idle, you should see 30 to 50 PSI. If not, replace the active fill valve. With the engine at low idle,

rotate the grapple. You should see 70 to 80 PSI. If not, replace the counter pressure valve. See Figure 1 and 2.

Figure 1

HYDRAULIC COLLECTOR MAINTENANCE

(SYMPTOMS OF A DEFECTIVE COLLECTOR)

ADD TEST TEE WITH

GAUGE INTO T3 PORT

CAP HOSE AND

PLUG LSP PORT

UPPER VALVE

BANK

CAP HOSE AND

PLUG P1 PORT

Summary of Contents for 495B SD

Page 3: ...Introduction...

Page 7: ......

Page 16: ...Maintenance...

Page 19: ...Operation and Maintenance Manual 495B ML TM S 19 Last Updated 08 31 2016 SERVICE SCHEDULE...

Page 29: ...Hydraulic...

Page 57: ...Electrical...

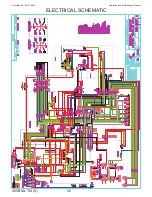

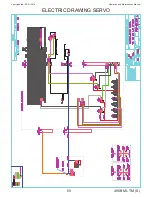

Page 58: ...Operation and Maintenance Manual Last Updated 08 31 2016 495B ML TM S 58 ELECTRICAL SCHEMATIC...

Page 78: ...Maintenance...

Page 88: ...Operation and Maintenance Manual Last Updated 08 31 2016 495B ML TM S 88 Structural...

Page 95: ...Trouble Shooting...