2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to

Sys Config

;

press ENTER key.

4. Press UP or DOWN keys to scroll to

Zone 1

,

Zone 2

or

Zone 3

; press ENTER key.

5. Press UP or DOWN keys to scroll to

Alarm

Setpoints A2-8

(Zone 1),

Alarm Setpoints A3-8

(Zone 2) or

Alarm Setpoints A4-8

(Zone 3

)

.

6. Press ENTER key to scroll to the variable labeled

High Temp

(see Figure 13).

7. Press UP or DOWN keys to adjust setpoint.

High Temperature 2 Alarm

If the highest temperature sensor value in a zone is

above the high temperature 2 setpoint, an alarm will

be generated for that zone. When this alarm is present,

the units will emergency cool in this zone. Additionally,

a relay output will be actuated from the LC to provide

remote notification of the event.

NOTE:

This alarm is per zone. If each zone is meant to

operate within the same alarm parameters, each

zone will need to be set accordingly.

To adjust the high temperature 2 alarm setpoint:

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to

Sys Config

;

press ENTER key.

4. Press UP or DOWN keys to scroll to

Zone 1

,

Zone 2

or

Zone 3

; press ENTER key.

5. Press UP or DOWN keys to scroll to

Alarm

Setpoints A2-9

(Zone 1),

Alarm Setpoints A3-9

(Zone 2) or

Alarm Setpoints A4-9

(Zone 3

)

.

6. Press ENTER key to scroll to the variable labeled

High Temp 2

(see Figure 13).

7. Press UP or DOWN keys to adjust setpoint.

To change the direction of the remote notification relay

output:

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to

IO Config

;

press ENTER key.

4. Press UP or DOWN keys to scroll to

Digital Out

Config C3

.

5. Press ENTER key to scroll to the variable in the

table that intersects

HiTemp

and

Dir

(see Figure

14).

6. Press UP or DOWN key to change direction.

When the

Val

(value) is

OFF,

the relay is not in an

alarm condition. When the

Val

(value) is

ON,

the relay

is in an alarm condition. The relay connections for the

high indoor temperature 2 alarm are on the LC6000

terminal block; see Table 6 on page 34 for terminal

block index.

Emergency Off Alarm

If the LC gets an input from a smoke detector or similar

device, an alarm will be generated and all units will be

shut down. Additionally, a relay output will be actuated

from the LC to provide remote notification of the event.

The emergency off input can be configured to accept

either normally open or normally closed inputs. The

controller is defaulted to normally open and a jumper is

placed across the terminals of the input (#6 and #7).

When this jumper is removed, the alarm will become

active.

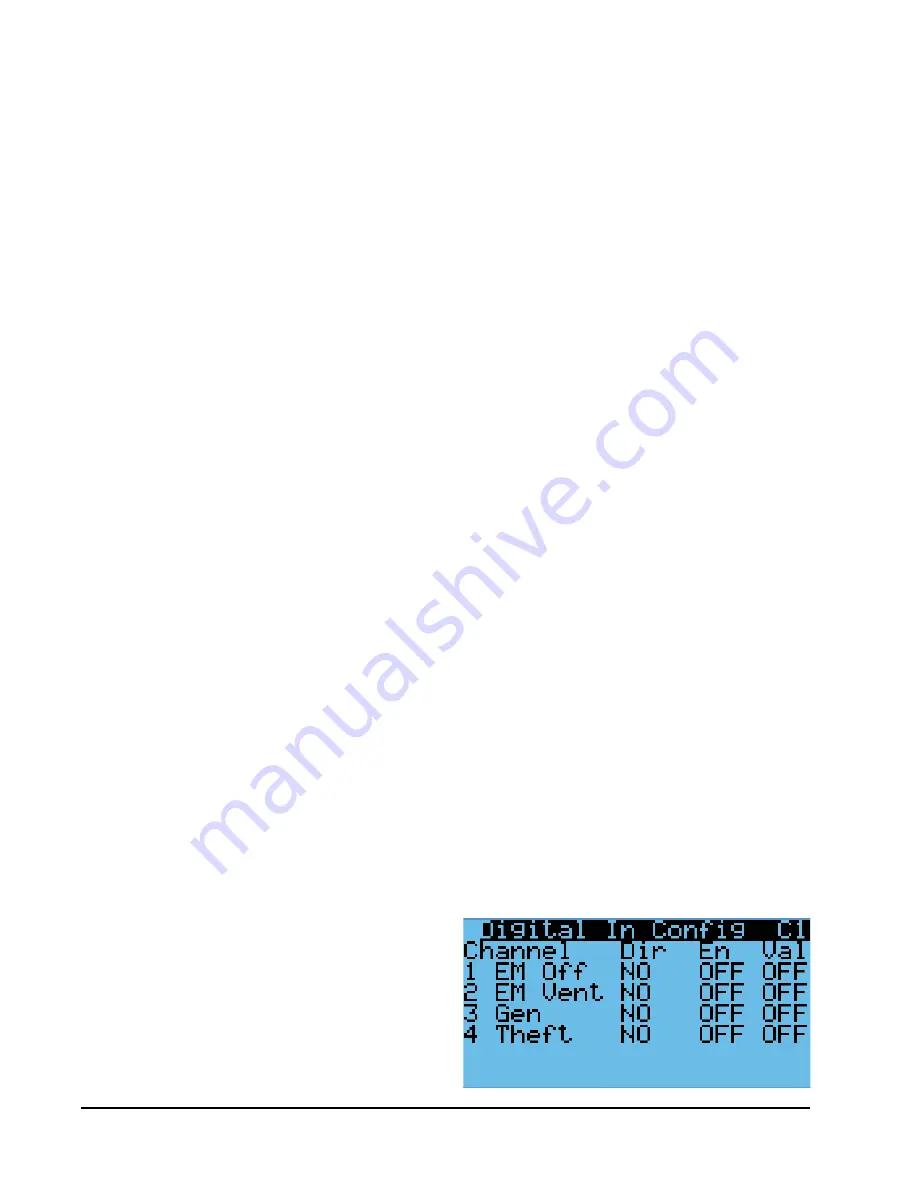

To change the direction of the emergency off input:

1. Press MENU key to go to the Main Menu screen.

2. Use UP or DOWN keys and ENTER key to enter

USER password 2000.

3. Press UP or DOWN keys to scroll to

IO Config

;

press ENTER key.

4. Press UP or DOWN keys to scroll to

Digital In

Config C1

.

5. Press ENTER key to scroll to the variable in the

table that intersects

EM

Off

and

Dir

(see Figure 15).

6. Press UP or DOWN key to change direction.

Emergency Off (EM Off)

Dir

(direction) is the position

of the smoke detector contacts in the event of smoke.

NO

is normally open;

NC

is normally closed.

EM Off

En

(enable) allows the LC controller to monitor

the smoke detector when set to

ON

. When set to

OFF

,

the LC controller ignores the smoke detector.

EM Off

Val

(value) of

ON

indicates a smoke event. A

Val

(value) of

OFF

indicates no smoke event.

Smoke detector connections (emergency off input) are

on the LC6000 terminal block; see Table 6 on page 34

for terminal block index.

FIGURE 15

Adjust Emergency Off, Emergency Vent or

Generator Alarm Input Direction

Manual 2100-669F

Page

16 of 37