Control Module Configuration

20

Banner Engineering Corp.

•

Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

5.2.3 Blanking

If a machine fixture or other equipment will continuously block

one or more beams, the affected beam channels may be blanked.

The Blanking option causes the control module to ignore the

status of blanked beams for measurement mode calculations.

For example, if a machine fixture blocks one or more beams

during System operation, the output data will be incorrect; if

beams blocked by the fixture are blanked, the output data will be

correct. Blanking may be configured using the push-button

Alignment switch on the control module, or by using the system

software and a computer.

Push-Button Blanking Setup Routine

To specify blanking using the control module’s Alignment

switch

, (see Figure 5.4) position the object or part to be ignored

in the path of the beams before beginning the Alignment routine.

Press the Alignment switch for 3 seconds; the Diagnostics

Indicator will show the letter ‘

A

’. Press the Alignment switch

again, but this time only momentarily (about 0.5 seconds max.).

The Diagnostics Indicator will show the letter ‘

b

’ to indicate it is

ready to “learn” the blanking pattern. Again, momentarily press

the Alignment switch to set the blanking fields. Both the control

module and the receiver will indicate a clear condition (green

Align indicator ON) and the Diagnostics Indicator will show ‘

A.

’

(the period following the ‘A’ indicates that blanking is in use).

The beams blocked during the routine are now blanked. To return

to Run mode, again press the Alignment switch for 3 seconds.

When the System is ready for operation and configured for beams

to be blanked, the period on the Diagnostics Indicator will remain

lit, showing ‘

—.

’ (see Figure 5-4).

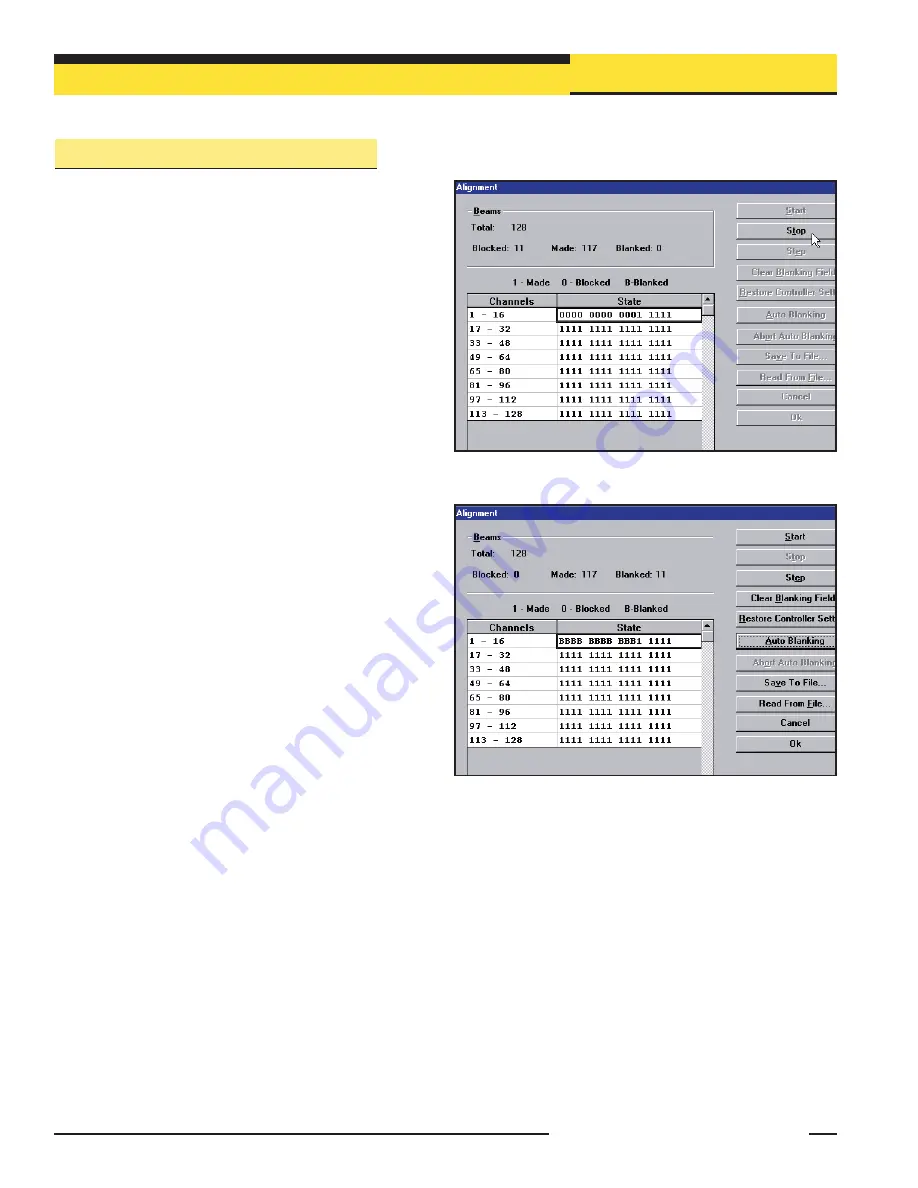

System Software Blanking Setup Routine

To specify blanking using the System software,

the procedure

is similar. Position the object to be blanked in the path of the

beams (this can be done at any time before beginning the

blanking routine). Perform the Ping routine to select the proper

control module, then press

F8

or select the

Alignment

option

from the MINI-ARRAY menu. From the screen menu (Figure 5-6),

select

Stop

; the Diagnostics Indicator on the control module will

show the letter ‘

A

’. Select

Auto Blanking

(Figure 5.7); the Diagnostics Indicator will show

the letter ‘

b

’. Select

Accept Auto Blanking

; both the control module and the receiver will

indicate a clear condition (green Align indicator ON) and the Diagnostics Indicator will

show ‘

A

.’ (the period following the ‘A’ indicates that blanking is in use). The beams

blocked during the routine are now blanked and appear as the letter ‘

B

’ on the grid instead

of ‘

0

’; if you wish to blank additional beams, use the ‘

Edit

’ key to manually set additional

blanking (see next page). To leave Alignment mode, select ‘

OK

’. When the System is ready

for operation and configured for beams to be blanked, the period on the Diagnostics

Indicator will remain lit, showing ‘

—.

’ (see Figure 5-4).

Scanning Mode Limitations for Blanking:

All blanking features are available with Continuous Scan mode. For single-and double-

edge scan, blanking is limited to four blanking fields. Other blanking features are ignored.

Figure 5-6. Alignment screen, showing beams #1-11 blocked

Figure 5-7. Alignment screen, showing beams #1-11 blanked