Technical data • 8JSA3 - Technical data

36

8JSA user's manual V1.00

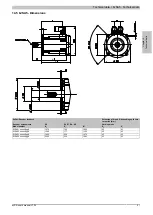

12.4 Maximum shaft load

Note the information in section

"Load capacity of the shaft end and bearing" on page 70

conditions".

0

5

10

15

20

25

150

200

250

300

350

400

450

500

550

500

1000

1500

3000

4500

6000

Distance x [mm]

Pe

rm

is

si

bl

e

ra

di

al

fo

rc

e

F

r

[N

]

Maximum axial force: F

amax

= 48 N

F

rmax

(Smooth shaft)

F

rmax

(Keyed shaft)

Av

er

ag

e

sp

ee

d

n

av

g

[r

pm

]