ENGLISH

33 / 44

0006160028_201510

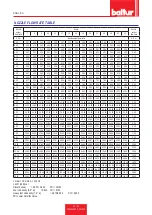

MAINTENANCE TIME

COMBUSTION HEAD

GAS

DIESEL

ELECTRODES

VISUAL INSPECTION OF THE INTEGRITY OF CERAMICS. TIP GRIN-

DING, CHECK DISTANCE, CHECK ELECTRICAL CONNECTION.

YEARLY

YEARLY

FLAME DISK

INTEGRITY VISUAL INSPECTION FOR POSSIBLE WARPING, CLEA-

NING

YEARLY

YEARLY

COMBUSTION HEAD COMPONENTS

INTEGRITY VISUAL INSPECTION FOR POSSIBLE WARPING, CLEA-

NING

YEARLY

YEARLY

LIQUID FUEL NOZZLES

REPLACEMENT

N.A.

YEARLY

INSULATING SEAL

VISUAL INSPECTION OF LEAK TIGHTNESS AND POSSIBLE REPLA-

CEMENT

YEARLY

YEARLY

AIR LINE

GAS

DIESEL

AIR SHUTTER BEARINGS

GREASING, (NOTE: apply only to burners with bearings to be greased) 6 MONTHS 6 MONTHS

AIR FAN

CLEANING

YEAR

YEAR

AIR PRESSURE SWITCH

CLEANING

YEAR

YEAR

AIR PRESSURE PIPES AND OUTLET

CLEANING

YEAR

YEAR

SAFETY COMPONENTS

GAS

DIESEL

FLAME SENSOR

CLEANING

YEAR

YEAR

GAS PRESSURE SWITCH

OPERATIONAL TEST

YEAR

YEAR

VARIOUS COMPONENTS

GAS

DIESEL

ELECTRIC MOTORS (BEARINGS/COO-

LING FAN)

CLEANING, (see if the supplier's indications were provided)

YEAR

YEAR

LEVERS/STRAP SYSTEM/BALL JOINTS

(BACKLASH/LUBRICATION)

CHECK FOR POSSIBLE BACKLASH

YEAR

YEAR

HOSES

REPLACEMENT

N.A.

5 YEARS

FUEL LINE

GAS

DIESEL

PUMP FILTER

CLEANING

YEAR

YEAR

LINE FILTER

CLEANING/REPLACEMENT (SPARE CARTRIDGE?)

YEAR

YEAR

GAS FILTER

REPLACE THE FILTER

YEAR

YEAR

COMBUSTION PARAMETERS

GAS

DIESEL

CO TEST

COMPARISON WITH THE VALUES RECORDED UPON THE EQUIP-

MENT START-UP

YEAR

YEAR

CO2 TEST

COMPARISON WITH THE VALUES RECORDED UPON THE EQUIP-

MENT START-UP

YEAR

YEAR

TEST OF FUMES ACCORDING TO

BACHARACH INDEXES

COMPARISON WITH THE VALUES RECORDED UPON THE EQUIP-

MENT START-UP

YEAR

YEAR

NOX TEST

COMPARISON WITH THE VALUES RECORDED UPON THE EQUIP-

MENT START-UP

YEAR

YEAR

IONISATION CURRENT TEST

COMPARISON WITH THE VALUES RECORDED UPON THE EQUIP-

MENT START-UP

YEAR

YEAR

FUME TEMPERATURE TESTING

COMPARISON WITH THE VALUES RECORDED UPON THE EQUIP-

MENT START-UP

YEAR

YEAR

GAS PRESSURE REGULATOR

PRESSURE MEASUREMENT UPON START-UP

YEAR

N.A.

IMPORTANT

In case of heavy use or particular fuels, the maintenance frequency must be increased and adapted to the use conditions according

to the maintenance technician's indications.

Summary of Contents for TBML 50 ME

Page 2: ......

Page 40: ...SCHEMI ELETTRICI ITALIANO 38 44 0006160028_201510...

Page 41: ...ITALIANO 39 44 0006160028_201510...

Page 42: ...ITALIANO 40 44 0006160028_201510...

Page 43: ...ITALIANO 41 44 0006160028_201510...

Page 44: ...BT1 BA BP I1 I2 I3 I4 ITALIANO 42 44 0006160028_201510...

Page 46: ...ITALIANO 44 44 0006160028_201510...

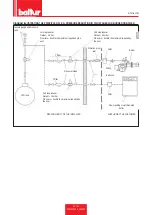

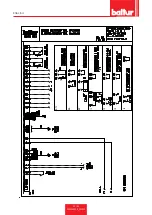

Page 84: ...ENGLISH 38 44 0006160028_201510 WIRING DIAGRAMS...

Page 85: ...ENGLISH 39 44 0006160028_201510...

Page 86: ...ENGLISH 40 44 0006160028_201510...

Page 87: ...ENGLISH 41 44 0006160028_201510...

Page 88: ...ENGLISH 42 44 0006160028_201510 BT1 BA BP I1 I2 I3 I4...

Page 90: ...ENGLISH 44 44 0006160028_201510...

Page 91: ......