ENGLISH

5 / 26

0006160227_201702

Special instructions for using gas.

•

Check that the feed line and the train comply with current

standards and regulations.

•

Check that all the gas connections are properly sealed.

•

Do not leave the equipment on when it is not in use and always

close the gas cock.

•

If the user is away for some time, close the main gas feed valve

to the burner.

•

If you smell gas:

- do not operate electrical switches, the phone or any other

object that can cause sparks;

- immediately open doors and windows to create a draught to

clear the air in the room;

- close the gas cocks;

- have professionally qualified personnel correct the fault.

•

Do not block ventilation openings in the room where there is gas

equipment or dangerous situations may arise with the build up

of toxic and explosive mixtures.

RESIDUAL RISKS

•

In spite of the accurate product planning according to the

regulations in force, residual risks may still be present during

correct use. They are indicated on the burner by means of

specific Pictograms.

CAUTION

Mechanical parts in motion.

CAUTION

Materials at high temperatures.

CAUTION

Energised electrical switchboard

INSTRUCTIONS ON ELECTRICAL SAFETY

•

Check that the equipment is properly grounded according to the

safety standards in force.

•

Do not use the gas pipes to ground electrical equipment.

•

If in doubt, call for a careful electrical check by a qualified

technician, since the manufacturer will not be liable for any

damage caused by a poor ground connection.

•

A professional check should be carried out to ensure that

the electrical installation is adequate for the maximum output

absorbed by the system. This is indicated on the data plate.

•

Make sure that the system cable cross-section is suitable for

the power absorbed by the equipment.

•

The use of adaptors, multiple plugs and/or extension leads to

supply power from the mains to the appliance is not allowed.

•

For the connection to the mains, fit an omnipolar switch with a

contact opening gap equal to or greater than 3 mm in accordance

with current safety regulations (Overvoltage category III).

•

Use only double insulated cables with external thickness of at

least 1mm for the power supply of the burner.

•

Unsheathe the external insulating cover of the power cable to

the necessary extent for the connection, thus avoiding the wire

from coming into contact with metal parts.

•

The electrical supply to the burner must have neutral to ground

connection. In the case of a ionisation current check with neutral

not to ground, it is essential to make a connection between

terminal 2 (neutral) and the ground for the RC circuit.

•

If the user is away for some time, close the main gas feed valve

to the burner.

•

The use of any components that use electricity means that

certain fundamental rules have to followed, including the

following:

- do not touch the equipment with parts of the body that are

wet or damp and/or with damp feet

- do not pull on electrical cables;

- do not leave the equipment exposed to atmospheric agents

(such as rain or sun etc.) unless there is express provision

for this.

- do not allow the equipment to be used by children or

inexperienced persons.

- The power supply cable for the equipment not must be

replaced by the user. If the cable is damaged, turn off

the equipment. To replace the cable, contact exclusively

qualified personnel.

- If you decide not to use the equipment for a while it is

advisable to switch off the electrical power supply to all

components in the system that use electricity (pumps,

burner, etc.).

•

Use flexible cables compliant with standard EN60335-1:

- if PVC sheathed at least H05VV-F

- if rubber sheathed at least H05RR-F

- if unsheathed at least FG7 or FROR

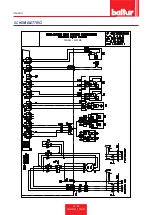

Summary of Contents for TBG 2000 ME

Page 2: ......

Page 24: ...ITALIANO 22 26 0006160227_201702 SCHEMI ELETTRICI TBG 480 2000 ME ...

Page 25: ...ITALIANO 23 26 0006160227_201702 TBG 480 2000 ME ...

Page 26: ...ITALIANO 24 26 0006160227_201702 TBG 480 2000 ME ...

Page 27: ...ITALIANO 25 26 0006160227_201702 TBG 480 2000 ME ...

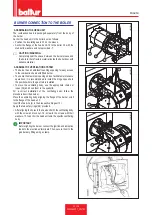

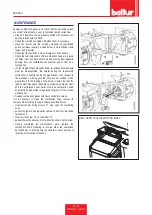

Page 50: ...ENGLISH 22 26 0006160227_201702 WIRING DIAGRAMS TBG 480 2000 ME ...

Page 51: ...ENGLISH 23 26 0006160227_201702 TBG 480 2000 ME ...

Page 52: ...ENGLISH 24 26 0006160227_201702 TBG 480 2000 ME ...

Page 53: ...ENGLISH 25 26 0006160227_201702 TBG 480 2000 ME ...

Page 55: ......