1

Intended use

The BTL magnetostrictive linear position sensor, together

with a machine controller (e.g. PLC), comprises a position

measuring system. It is intended to be installed into a

machine or system and used in the industrial sector.

Flawless function in accordance with the specifications in

the technical data is ensured only when using original

Balluff accessories. Use of any other components will void

the warranty.

Opening the BTL or non-approved use are not permitted

and will result in the loss of warranty and liability claims

against the manufacturer.

General safety notes

Installation

and

startup

may only be performed by

trained specialists.

The

operator

is responsible for ensuring that local safety

regulations are observed. In particular, the operator must

take steps to ensure that a defect in the BTL will not result

in hazards to persons or equipment.

If defects and unresolvable faults occur in the BTL, take it

out of service and secure against unauthorized use.

Downloading further instructions

A complete user's guide can be downloaded from the

Internet at

www.balluff.com

or requested via e-mail from

.

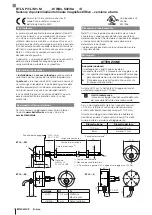

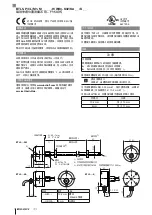

Dimensions and function

The BTL contains the waveguide which is protected by an

outer stainless steel tube (rod). A magnet is moved along

the waveguide. This magnet is connected to the system

part whose position is to be determined.

The magnet defines the position to be measured on the

waveguide.

Installation

NOTICE!

Interference in function

Improper installation can compromise the function of the

BTL and result in increased wear.

►

The mounting surface of the BTL must make full

contact with the supporting surface.

►

The bore must be perfectly sealed (O-ring/flat seal).

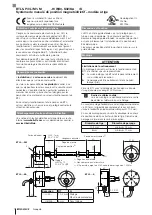

Screw the BTL with mounting thread into the mounting

hole (max. torque 100 Nm).

Radial cable outlet

During installation, the direction of the cable

outlet is determined by the thread.

For horizontal assembly with nominal lengths > 500 mm,

support the rod and tighten it at the end if necessary (only

possible with a diameter of 10.2 mm).

If installed in a hydraulic cylinder, the magnet should not

make contact with the rod. Minimum bore diameter in the

support piston:

Rod diameter

Bore diameter

10.2 mm

At least 13 mm

8 mm

At least 11 mm

BTL5-P/I/L/M1-M _ _ _ _ -H/W(8) -S32/KA _ _ /K _ _

Magnetostrictive Linear Position Sensor – Rod Style

english

The CE Mark verifies that our products

meet the requirements of the current

EMC Directive.

UL approval

File No.

E227256

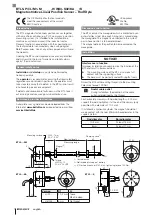

Ø 65

21

35

~42

0.5 Ø 25

~20

~20

10

43

25

~12

60

Ø

D1

G

10

0.5 Ø 25

Thread

H: M18×1.5

W: 3/4"-16UNF

H: 40 -1mm

W: 2" -0.04"

Mounting surface

Damping zone1)

BTL5…-KA _ _

BTL5…-K_ _

BTL5…-S32

Magnet 2)

1)

1)

Unusable area

2)

Not included in scope of delivery

3)

Ø 5 for hook spanner Ø 65, max. tightening torque 100 Nm

Nominal length =

Measuring range

Version

D1

G

…-H/W-…

10,2 mm

Thread

M4x4/6 deep

…-H8/W8-…

8 mm

No thread

3)