Optional Accessories

23

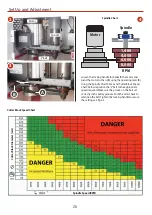

5

6

7

8

Shim

Washer

Clamping block

Routine Maintenance

• Keep the cutter block clean and free from dust build up.

• Check the cutter block regularly for chipped blades and

damage to the block i.e cracks in the cutter block.

• When changing the cutter block, remove the cutter

block and place safely away, clean the spindle arbor by

spraying PTFE Lubricant over the shaft and install a new

cutter block.

WARNING!! DISCONNECT THE MACHINE

FROM THE MAINS BEFORE CONTINUING!

• Opening the access door for the spindle moulder, check

the belt tension. If the belt is loose, loosen the motor

clamping handle and rotate the operating handle until the

belt is under tension again. Tighten the motor clamping

handle to keep the tension.

• After several months of constant use the condition of

the chains, sprockets,tension of the drive belts and the

threaded drive shafts of the rise and fall mechanisms

will need to be checked. That may require a service

engineer to oversee the job.

If you find that the machine is not performing as it should

please contact our “Technical Support Team” on 03332 406406

or email: mailto:[email protected]

Threaded shaft

Drive assembly

Clamping handle

Motor pulley

Spindle pulley

‘V’ Belt

Operating

handle