36 (40)

8.2

Inspection of metal structures

Also the metal structures of the attachment must be inspected regularly. Check visually for damages and

inspect the quick attach brackets and their surrounding area carefully. The attachment must not be used if it is

deformed, cracked, or torn.

Welding repairs are only allowed to be carried out by professional welders. When welding, only methods and

additives suited for steel used in bucket must be used. For more information about repairs contact your

nearest service point.

8.3

Cleaning the attachment

Clean the attachment regularly to prevent accumulation of dirt which is more difficult to remove. A pressure

washer and mild detergent can be used for cleaning. Do not use strong solvents, and do not spray directly at

the hydraulic components, or at the labels on the attachment.

Clean the collector box thoroughly, do not leave water in the collector. Empty and rinse the water spraying

system completely.

8.4

Brush

The nylon brush bristles have a long service life in normal operating conditions. As the brush wears down its

diameter decreases, and eventually it will not throw material at sufficient speed for good collecting

performance.

The brush consists of several parallel discs connected on a shaft. If you notice that a specific part of the brush

has damaged or worn clearly more than the rest of it, the discs may be rearranged on the shaft to achieve

more even wearing. The damaged brush discs can be changed individually, but usually a larger section

should be replaced to keep the performance of the broom even. If the damaged brush discs are worn clearly

more than new ones, all of the discs should be replaced at once. Steel bristle discs may also be available,

contact your dealer.

To replace the brush discs the broom shaft must to be removed. The brush is made denser at the ends of the

shaft by setting three discs the same way round at the both ends of the shaft. The discs are held together on

the shaft by a tightening flange. When tightening the flange, the total compression of the discs along the shaft

must not be more than 5 – 10 mm.

8.4.1

Side brush

The side brush has both nylon and steel bristles. Keep the side brush and its pivot joints clean, other

maintenance is not needed.

8.4.2

Side bristle skirts and rubber edge plate

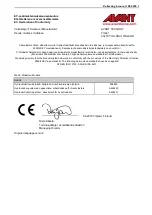

For the best collecting operation and preventing the

spreading of dust, monitor the side and rear bristle skirts

and the rubber lip plate, shown in adjacent figure.

Replace if necessary.

1.

Rubber edge plate A422983

2.

Sibe bristle skirt (2 pcs) A423444

3.

Rear bristle skirt (2 pcs) A423445

Summary of Contents for A36883

Page 2: ...Collecting broom 1100 2018 1 ...

Page 40: ......