23(24)

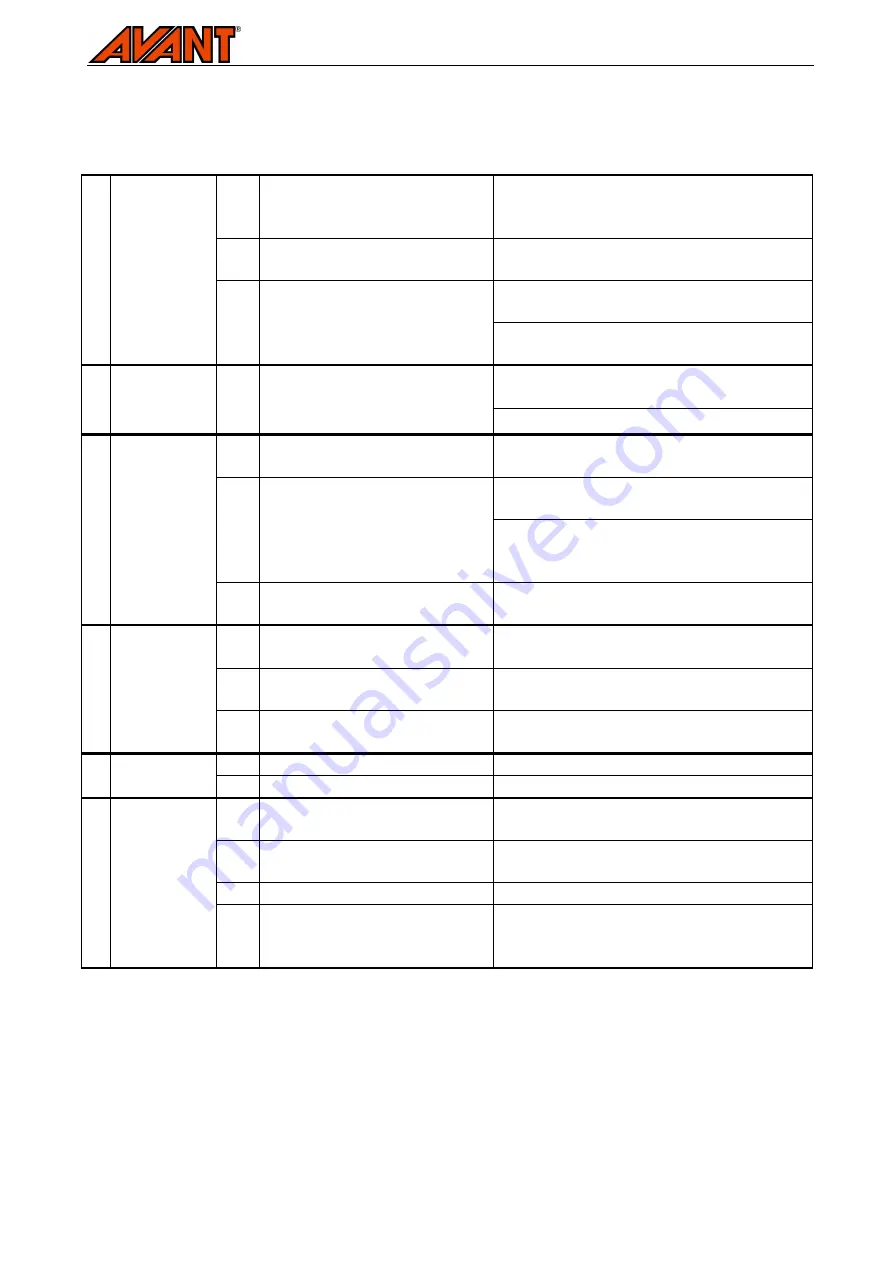

7.6.

Troubleshooting

1.1

Badly or wrongly connected

hydraulic hoses, or fault in

loader valve

Check hose connectors and operation of

hydraulic valve.

1.2

Excessive

compressed

air

pressure

Release pressure by using a pneumatic tool

or with manual drain valve.

Make sure that oil pressure and flow input

are within specifications.

1

Compressor

will not run,

even

when

loader

is

running with

auxiliary

hydraulics

turned on

1.3

Fault in hydraulic system of

compressor

Make sure that there are no leaks. Contact

service.

Release pressure by using a pneumatic tool

or by opening manual drain valve.

2

Compressor

starts hardly

2.1

Excessive

compressed

air

pressure

Check stopping system components.

3.1

Faulty safety valve or wrong

setting

Check condition and setting of safety valve.

Replace if necessary.

Make sure that oil pressure and flow input

are within specifications. Adjust as needed.

3.2

Fault in hydraulic system

Check the condition of hydraulic motor and

possibility of internal leaks. Contact service to

check or repair hydraulic motor.

3

Air pressure

does

not

reach

set

level

3.3

Clogged air filter or intake

manifold

Check, clean and/or replace.

4.1.

Air connector damaged or tool

failure

Check and fix possible fault.

4.2

Speed control damaged or

adjusted incorrectly

Contact service.

4

Compressor

does

not

create

pressure

4.3

Clogged air filter or intake

manifold

Check, clean and/or replace.

5.1

Wrong type of oil

Use oil suitable for operating conditions.

5

Excessive oil

consumption

5.2

Worn piston rings

Check and fix possible fault.

6.1

Dirty compressor block, clogged

cooling fan grill

Check and clean.

6.2

High ambient temperature

Extra

cooling

must

be

arranged

for

compressor.

6.3

Low oil level

Add oil to specified marker.

6

Compressor

overheats

6.4

Overheating hydraulic oil heats

compressor

Allow hydraulic system to cool before

continuing. Check operation and condition of

loader oil cooler.