-|Transparent Guide|-

Wiring of Output

■ S14, S24, S34, S44, S54 : P channel safety outputs

The instantaneous or off-delay safety outputs go to ON or OFF based on the safety

inputs, feedback start input, logic input, and input signals of non-contact door switch.

•

Leave unused safety outputs in the OPEN state.

•

Configure a protection circuit against the counter electromotive force when

connecting inductive loads.

•

To expand the number of safety outputs in the form of contacts, connect the

expansion cable of the expansion relay unit to advanced unit or the expansion

connector of non-contact door switch unit, and connect the loop connector to the

expansion relay unit located at the end of position.

•

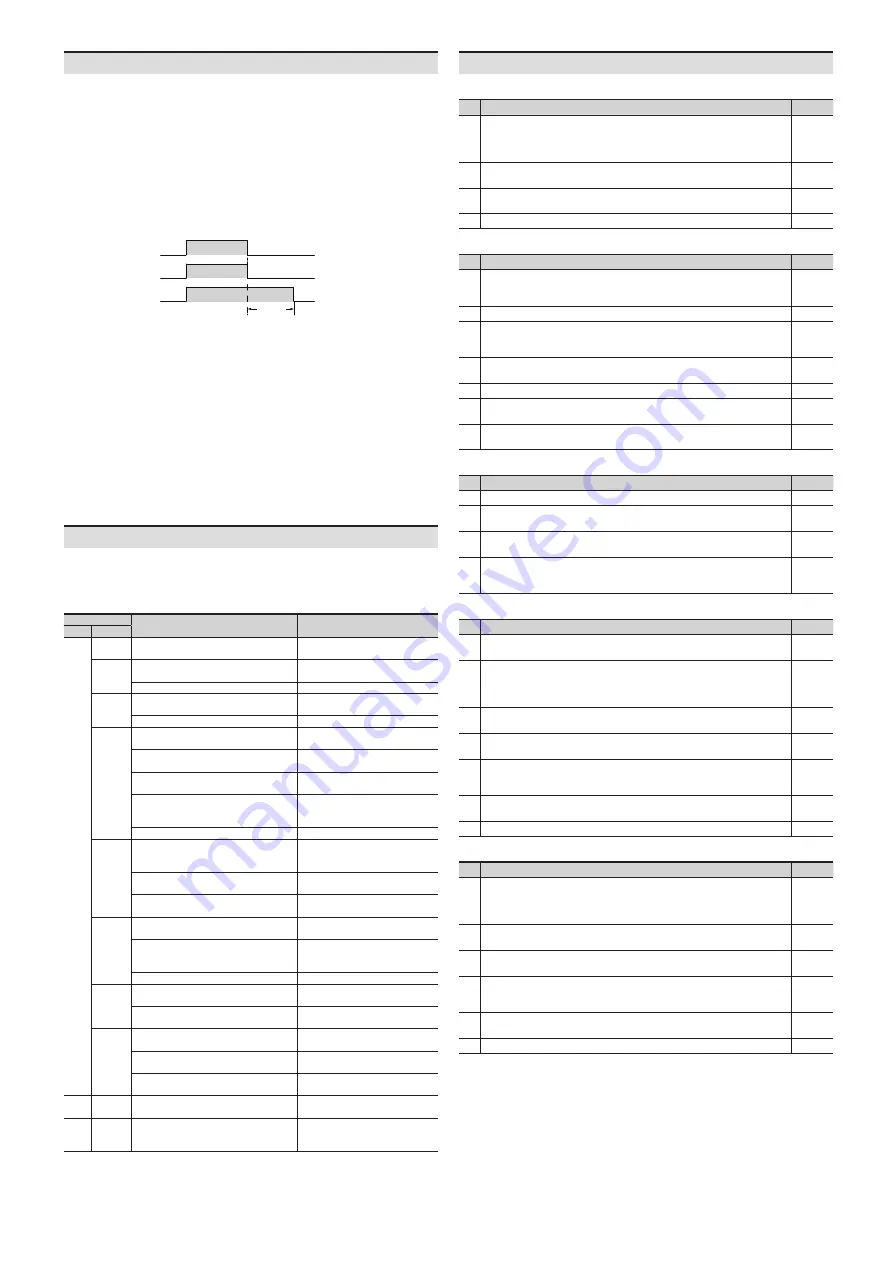

Operation of safety output and safety off-delay output based on the safety input signal

Safety input

ON

OFF

ON

OFF

ON

OFF

Safety instantaneous

output

Safety off-delay

output

Off-delay

set time

■ 13/14, 23/24, 33/34 (37/38), 43/44 (47/48)

: Safety outputs of relay unit

The instantaneous or off-delay safety outputs go to ON or OFF based on the safety

inputs, feedback start input.

•

Leave unused safety outputs in the OPEN state.

■ X1: Auxiliary output 1

When the instantaneous safety outputs are ON, the X1 auxiliary output goes to ON.

When the instantaneous safety outputs are OFF, the X1 also goes to OFF.

•

Leave unused auxiliary output in the OPEN state.

■ X2: Auxiliary output 2

X2 auxiliary output goes to ON when the ERR indicator turns on or flashes.

•

Leave unused auxiliary output in the OPEN state.

Error Indication

When an error occurs, the ERR indicator and other indicators turn on or flash to notice

the cause of error.

Be sure to check and take measures according to the table below, and turn the power

on again. If the measures are not valid, please contact the Autonics.

Indicator

Cause

Check and measures

ERR Others

ON

PWR

flashes

The power voltage is out of the allowable

range.

Check the supplied power voltage.

M1

flashes

Wiring error of safety input 1

Check the wiring to M11, M12

terminal.

Failure of internal circuit of safety input 1 Please contact the Autonics.

M2

flashes

Wiring error of safety input 2

Check the wiring to M21, M22

terminal.

Failure of internal circuit of safety input 2 Please contact the Autonics.

FB

flashes

Wiring error of feedback start input

Check the wiring to M51, M52 and

M53 terminal.

Internal circuit error of feedback start

input

Please contact the Autonics.

Error at the power of expansion relay unit Check the supplied power voltage

to the expansion relay unit.

Feedback error of the relay unit

Check the cable of expansion

relay unit and loop connector

connection.

Safety output error of the relay unit

Please contact the Autonics.

NS

flashes

Wiring error of input and output of the

non-contact door switch

Check the wiring to the D1 and

D2 terminal of non-contact door

switch.

Wiring error of series connection of the

non-contact door switch

Check the wiring to between the

non-contact door switches.

Failure of internal circuit of the non-

contact door switch

Replace the non-contact door

switch (SFN series).

AND

flashes

Wiring error of logic input

Check the wiring to M61 and M62

terminal.

Setting error of logic input

Check the setting values of SW1

and SW2 at switch for logic (AND)

input.

Failure of internal circuit of logic input

Please contact the Autonics.

OUT1

flashes

Wiring error of instantaneous safety

output

Check the wiring to instantaneous

safety output terminal.

Failure of internal circuit instantaneous

safety output

Please contact the Autonics.

OUT2

flashes

Wiring error of the off-delay safety output Check the wiring to the off-delay

safety output terminal.

Failure of internal circuit of the off-delay

safety output

Please contact the Autonics.

Setting error of the off-delay time

Check the setting value of the

switch for off-delay time.

Flash -

Error at internal circuit and output relay

of the expansion relay unit

Please contact the Autonics.

OFF M1 M2

flashes

The different input signal between safety

input 1 and safety input 2

Check the wiring to the safety

input devices. Check the input

sequence of safety inputs.

Check and Maintenance

■ Check installation conditions

Checklist

Check

1

The distance from hazardous zone or source of the machine to the product,

safety sensors connected to the product, installed location is equal to or

greater than calculated safety distance.

Safety distance: ()mm / Actual distance: ()mm

2

Installed in the environment without the material causing deformation such as

corrosion or ignition.

3

When installing the DIN rail or panel, the product is firmly fixed to prevent

separation.

4

There is no product damage or appearance problem.

■ Check wiring connection

Checklist

Check

1

The power supply used for devices related to the product and safety-related

functions is 24VDC, and a dedicated power supply meets the specified rated

specifications and is not connected to other devices or equipment.

2

When connecting power supply, the polarity is not connected in reverse.

3

The appearance of the wiring connected to the product is not damaged, such

as cracking, breakage, etc. of the outer shell, and there is no cause for damage

around the wiring.

4

In case of connecting more than two products, it is configured for the

dedicated series connection or mutual interference.

5

The wiring connected to the product is correctly connected to each purpose.

6

The wiring connected to the product is firmly fixed to prevent separation

during use.

7

In case of auxiliary output (AUX1,AUX2), it is configured to prevent the

connection to safety-related part of the control system.

■ Safety system-check in operation

Checklist

Check

1

Inspect without operator in hazardous zone or near the source of hazard.

2

The safety input signal is off while the machine is operating, then the safety

system immediately stops.

3

In case of the power shut down, the safety system stops and maintains the

status.

4

The actual machine response time (the time taken for the hazard source to

stop) is less than the calculated time

Calculated machine response time: ()ms / Actual machine response time: ()ms

■ Daily inspection

Checklist

Check

1

Accessible to hazardous zone or source of the machine only by passing through

the detection zone of the product.

2

The distance from hazardous zone or source of the machine to the product,

safety sensors connected to the product, installed location is equal to or

greater than calculated safety distance.

Safety distance: ()mm / Actual distance: ()mm

3

When installing the DIN rail or panel, the product is firmly fixed to prevent

separation.

4

The wiring connected to the product is firmly fixed to prevent separation

during use.

5

The appearance of the wiring connected to the product is not damaged, such

as cracking, breakage, etc. of the outer shell, and there is no cause for damage

around the wiring.

6

The input/output wiring of the product is firmly fixed to prevent separation

from each device.

7

There is no product damage or appearance problem.

■ Regular inspection

Checklist

Check

1

The distance from hazardous zone or source of the machine to the product,

safety sensors connected to the product, installed location is equal to or

greater than calculated safety distance.

Safety distance: ()mm / Actual distance: ()mm

2

When installing the DIN rail or panel, the product is firmly fixed to prevent

separation.

3

The wiring connected to the product is firmly fixed to prevent separation

during use.

4

The appearance of the wiring connected to the product is not damaged, such

as cracking, breakage, etc. of the outer shell, and there is no cause for damage

around the wiring.

5

The input/output wiring of the product is firmly fixed to prevent separation

from each device.

6

There is no product damage or appearance problem.