46

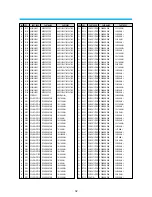

2). MAINTENANCE AND PERIODIC CHECKING LIST

!

MAINTENANCE AND GENERAL INFORMATION

A. To guarantee the perfect performance and the function of S1-MECHA Deck and also to use the tape for the

long life, you should conduct the periodic maintenance and checking.

• Replacement after checking

• Conduct replacement and checking without regard to the time used.

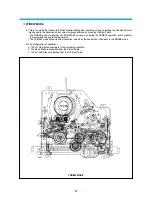

B. Cleaning of the rotary Head Drum

• To clean the rotary Head Drum, wet a towel with non-water added alcohol to clean the surface of the Drum

gently while rotating the Head Drum Assembly by hands slowly. (Warning: Do not clean while running the

Head Drum by motor.)

• Do not clean the Drum with the towel paralleling with Head tip vertically. (The Head tip is very fragile.)

C. Cleaning of the Tape Transporting section

Clean the tape Running Mechanism using the towel or the cotton swab wet with non-water added alcohol.

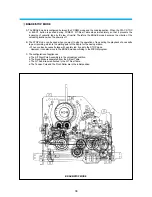

D. Cleaning of the operating parts.

Clean the operating parts using the towel or a cotton swab wet with non-water added alcohol.

E. Checking procedure

Do maintenance and checking according to the checking table.

@

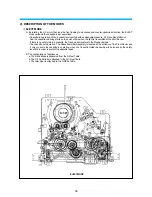

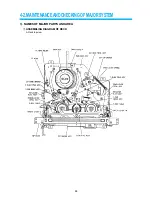

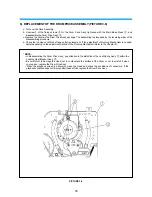

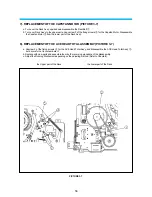

CLEANING AND GREASING

A. Cleaning

a. Tape Running Mechanism (Clean it every 500 hours of actual using time.)

• Tension Pole

• S-Slant Pole

• Ace Head

• S-Guide Post

• Video Head/Drum Ass’y

• T-Guide Post

• FE-Head

• T-Slant Pole

• Capstan shaft

• S-Guide Roller

• T-Guide Roller

• Pinch Roller

• Since the above mentioned parts directly contact with tapes, they can be easily contaminated by dust or

foreign matters. Also if they are contaminated by dust or foreign matters, they can affect the conditions of

display directly and damage the tapes.

• Before inserting a cassette tape into the deck, make sure these parts are completely dried after cleaning

with a non-water added alcohol.

b. Operating Parts (Clean it every 1,000 hours of actual using time.)

• S-Reel Table Post

• T-Reel Table Post

• Reel Gear Post

• Teeth and Surface of the Cam Gear

• Main Base Area

(S/T Slant Pole Ass’y and the moving area of Cassette Holder Ass’y)

B. Lubrication (Apply grease on parts every 2,000 hours of actual using time for lubrication.)

• S-Reel Table Post

• T-Reel Table Post

• Reel Gear Post

• Teeth and Surface of the Cam Gear

• Main Base Area

(S/T Slant Pole Ass’y and the moving area of Cassette Holder Ass’y)

• Apply grease on the above parts after cleaning with non-water added alcohol, but do not apply excessively.

Summary of Contents for AVP-7180

Page 16: ...3 2 CIRCUIT DIAGRAMS 15 1 CONNECTION DIAGRAM...

Page 17: ...16 2 POWER CIRCUIT DIAGRAM...

Page 19: ...18 3 SERVO SYSCON CIRCUIT DIAGRAM...

Page 21: ...20 4 VIDEO NOR AUDIO CIRCUIT DIAGRAM...

Page 23: ...22 5 Hi Fi PRE AMP CIRCUIT DIAGRAM...

Page 24: ...23 6 A V IN OUT CIRCUIT DIAGRAM...

Page 42: ...41 3 TIMING CHART OF S1 MECHA MECHANISM...

Page 46: ...45 B Deck bottom view...

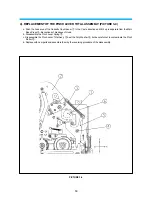

Page 50: ...SKETCH OF JIGS AND TOOLS 49...

Page 70: ...4 6 EXPLODED VIEW OF DECK AREA AND PARTS LIST 69 1 EXPLODING VIEW OF THE DECK...

Page 71: ...70...

Page 74: ...AUDIOVOX SPECIALTY MARKETS CO LP 23319 COOPER DR ELKHART IN 46514 219 266 1886...