9

6.6

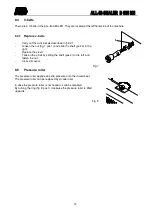

Preparation for use

After the All-in is connected to the power and properly checked. The machine can be put into operation.

−

Reset the emergency stop.

−

Set the main switch (POWER) to on (1).

−

Adjust the seal temperature (TEMP).

−

Adjust the operation speed (SPEED).

−

Turn on the MOTOR, FAN, and HEATER if necessary.

−

Press START/STOP to turn on the machine.

−

Let the machine heat up. The led TEMP/ACT stops flashing if the machine is at the set temperature.

Turn off the All-in normally with the cool run. If the All-in is not used for a longer period of time, set the main

switch (POWER) off and disconnect the power cord from the mains supply.

6.7

Emergency stop

In case of emergency the emergency stop (fig. 4) can be

activated. This causes the power supply to be shut off and the

machine to stop.

The emergency stop should only be used for emergencies and

not for a temporary switch off or stop of the machine.

The emergency stop is operated by means of pushing the red

button (fig. 4) on top of the machine. After each use of the

emergency stop it should be resetted by turning the red button in

the direction of the arrow.

After resetting the emergency stop, press the START/STOP-

button and the machine starts running again.

7

Specifications

7.1

Operational specifications

−

Operation speed

:

max. 10 meter per minute

−

Ambient temperature

:

+5ø . . . +40ø Celsius

−

Humidity

:

30% . . . 95% rel. (without condensation)

−

Fastening, fixing

:

The ALL-IN-SEALER is standing on 4 rubber feet

−

Explosion safety

:

Not to be used in explosive surroundings

−

Extraction, ventilation

:

To be used in ventilated spaces

7.2

Applocations not allowed

−

Packing in medical, sterile environment.

−

Use in an explosive surrounding.

−

Packing of poisonous, corrosive, irritating substances.

−

Packing of explosive materials.

−

Packing of (dangerous) dusty products.

Fig. 4

Summary of Contents for D 555 NH

Page 1: ...AUDION ELEKTRO ALL IN SEALER D 555 NH MANUAL D555 NH ENG Rev06...

Page 20: ...Appendix A1 14 Electrical circuit...

Page 21: ...Appendix A2 Electrical circuit...

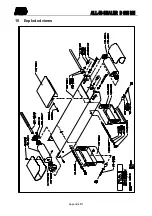

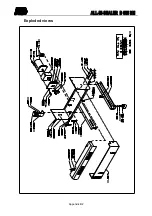

Page 22: ...Appendix B1 15 Exploded views...

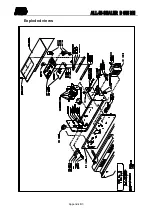

Page 23: ...Appendix B2 Exploded views...

Page 24: ...Appendix B3 Exploded views...

Page 25: ...Appendix B4 Exploded views...

Page 26: ...Appendix B5 Exploded views...