12

8.2

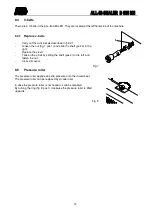

Heating elements

The heating elements are mounted in the heating plates. In order to obtain a good seal correct adjustment of

the heating plates is essential. Adjustment of the heating plates depends on the material properties.

8.2.1 Adjust heating plates

If very thick films need to be sealed, it may be necessary to

adjust the distance between the two heating and cooling

elements. If this is the case, then:

−

Carry out the activities as described in § 8.1

−

Turn the 4 nuts (fig. 6 pos 2) clockwise a few times to

raise the elements. Counter clockwise to lower the

elements.

−

Close all covers.

8.2.2 Replace heating elements

−

Remove the back cover.

−

Open the upper front cover.

−

Loosen the 3 screws (fig. 6 pos 1) to remove the complete moutingplate.

−

Disconnect the wiring of the heating elements.

−

Loosen the cup (fig. 6 pos 3) to replace the heating element (fig. 6 pos 4).

−

Connect the wiring and place the mounting plate.

−

Mount all covers.

8.3

PTFE-belts

The PTFE-belts prevent contact of the product to be sealed with the heating plates. The PTFE-belts should

never be folded as otherwise the folded part of the bands becomes a weak point during use.

8.3.1 Adjust PTFE-belts

Note :

Do not adjust the heating plates too tight to prevent unnecessary wear of the PTFE-belts.

See § 8.2.1.

The PTFE-belts are being tensioned by springs, which means that these belts do not need separate

adjustments.

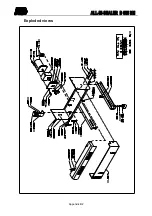

Fig. 6

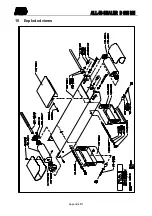

Summary of Contents for D 555 NH

Page 1: ...AUDION ELEKTRO ALL IN SEALER D 555 NH MANUAL D555 NH ENG Rev06...

Page 20: ...Appendix A1 14 Electrical circuit...

Page 21: ...Appendix A2 Electrical circuit...

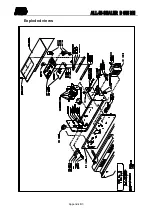

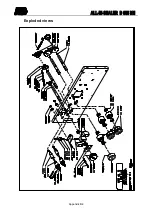

Page 22: ...Appendix B1 15 Exploded views...

Page 23: ...Appendix B2 Exploded views...

Page 24: ...Appendix B3 Exploded views...

Page 25: ...Appendix B4 Exploded views...

Page 26: ...Appendix B5 Exploded views...