Manual, F/T Sensor, Ethernet Axia

Document #9610-05-Ethernet Axia-09

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel:+1 919.772.0115 • Fax:+1 919.772.8259 •

51

Output Code:

When this statement’s comparison is found true, this 8-bit value will be bitwise

OR’ed with the Output Code values of all other true statements to form the

threshold output. Any set bits remain latched until the user issues a

Resent Latch

.

If no statements are true the threshold output is zero.

The value displays in hexadecimal, format 0x00. A user may type output codes

in hexadecimal format or in decimal. Bit pattern representing each thresholding

statement number are in the following table.

Table 6.3—Bit Patterns for Thresholds Breached

#:

Bit Pattern

#:

Bit Pattern

#:

Bit Pattern

#:

Bit Pattern

0:

0x00000001

4:

0x00000010

8:

0x00000100

12:

0x00001000

1:

0x00000002

5:

0x00000020

9:

0x00000200

13:

0x00002000

2:

0x00000004

6:

0x00000040 10: 0x00000400

14:

0x00004000

3:

0x00000008

7:

0x00000080 11: 0x00000800

15:

0x00008000

Get Statuses:

Click the

Get Statuses

button to update the static display of the threshold status. If

a threshold is unsatisfied, the threshold numbers are crossed out.

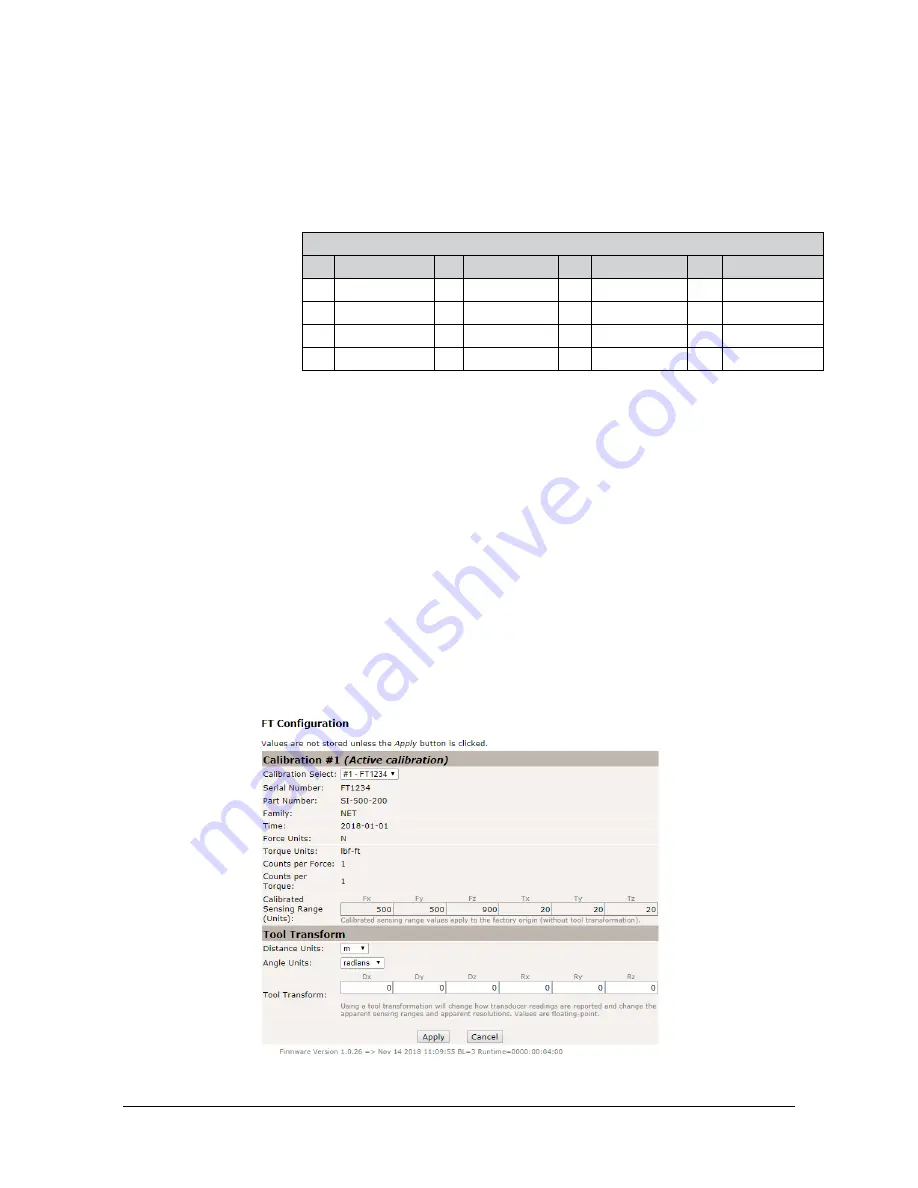

6.6 F/T

Configurations Page (config.htm)

On the

Configurations

page, a user may select the active calibration (

Section 15.3—Calibration Ranges

)

and tool transformation settings for the sensor system. When the user clicks the

Apply

button, the changes

on this page are implemented on the sensor. For more information about tool transformation feature, refer to

Section 4.7—Tool Transformation

.

From the

Configurations

page, a user may obtain the following values: the sensor’s

Serial Number

,

Part

Number

, calibration

Family

,

Time

or date the sensor was calibrated, force units, torque units, counts per

force, and counts per torque. Note that these are the same values that are in

“SET” Command Fields and Values

and

Section 11.2—Calibration Information (netftcalapi.xml)

For more information about how F/T values are scaled with the counts per force and counts per torque, refer

to

Section 4.4—Converting Counts Per Force/Torque to F/T Values

The

Calibrated Sensing Range

field displays the maximum rating for each axis of the selected calibration.

Figure 6.7

—Configurations Page