Manual, F/T Sensor, Ethernet Axia

Document #9610-05-Ethernet Axia-09

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel:+1 919.772.0115 • Fax:+1 919.772.8259 •

27

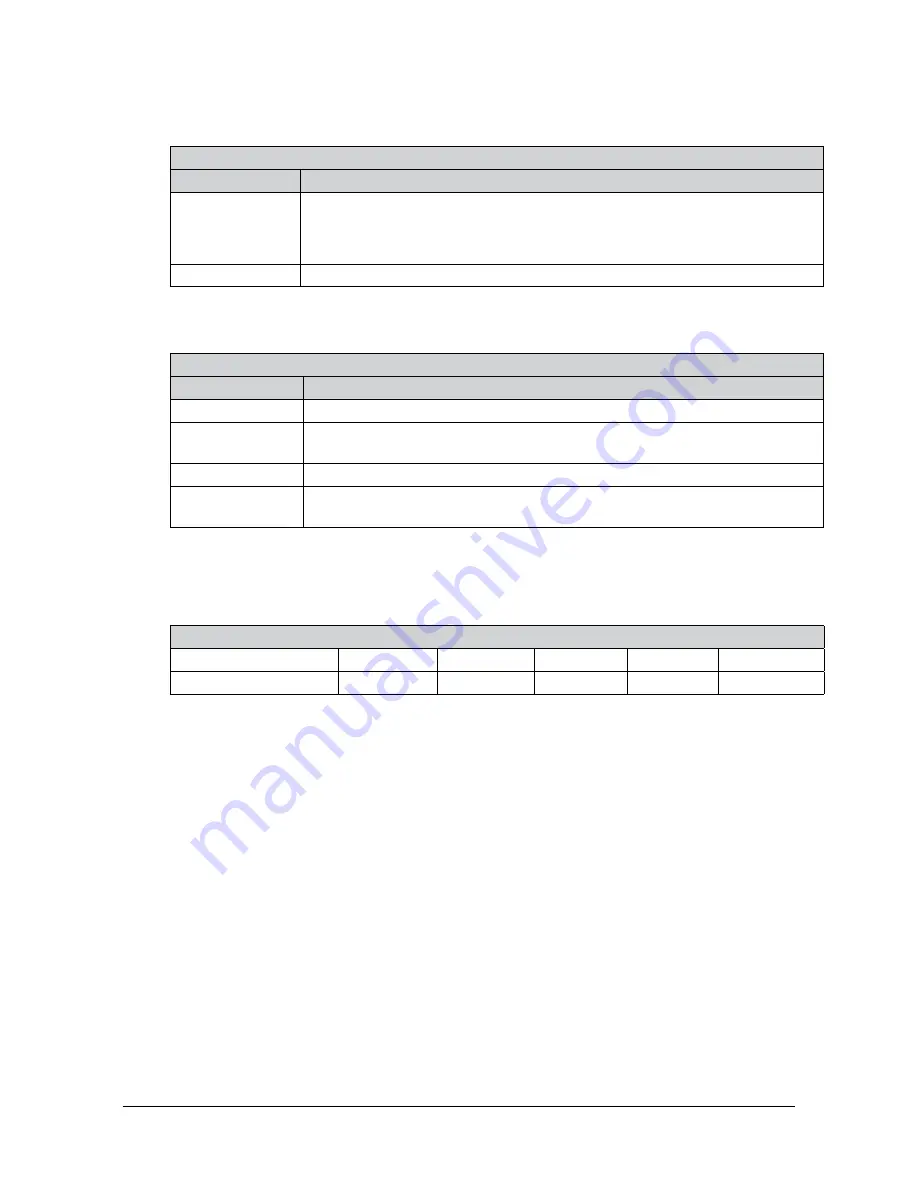

4.2.3 DIAG LED

One LED signals the communication status of the Ethernet Axia sensor interface as follows:

Table 4.3—DIAG LED

LED State

Description

Red

Indicates an error in the STATUS word except the following:

1. The gage temperature is out of range.

2. A gage is disconnected.

Off

Ethernet interface is in an operational state. No errors are found.

4.2.4 Sensor Status LED

One LED signals the health status of the sensor as follows:

Table 4.4—Sensor Status LED

LED State

Description

Off

The sensor is powering up and checking STATUS.

Red

Indicates an error in the STATUS word, or a

bad system status

reported on

the

System Information

webpage.

Green

Normal operation. Indicates no error in the STATUS word.

Red/Green

(Orange)

Indicates that a F/T axis is out of range.

4.3 Sample Rate

The power-on default sample rate is the rate the user set before removing power. The sample rate is stored

to nonvolatile memory. The

adcRate

Section 8.4—Console “CAL” | “SET” Command Fields and

controls the current sample rate. The following table lists the rounded and exact sample rates.

Table 4.5—Sample Rate

Rounded Sample Rate

0.5 kHz

1 kHz

2 kHz

4 kHz

8 kHz

Exact Sample Rate

488 Hz

976 Hz

1953 Hz

3906 Hz

7912 Hz

4.3.1 Sample Rate Versus Data Rate

The data rate is how fast data can be output over the Ethernet network.

If the data rate is faster than the sample rate, the customer sees duplicate samples output over the

network until the next sample is read internally. A faster data rate could be useful so that the sensor

sends data at the same rate that other devices in a customer’s system are outputting. For example: if

a discrete I/O device on the same network as the Axia is outputting data at 7,000 Hz, the customer

may want the Axia to be outputting data to the network at 7,000 Hz as well, even though the sensor

is not sampling that quickly internally.

If the sample rate is faster than the data rate, the customer does not receive the data from every

internal sample over the network. However, any filters that are enabled work based on the faster

internal sample rate, and so the sensor filters out higher frequency noise sources than if the filter is

operating at a slower data rate.

4.4 Converting Counts Per Force/Torque to F/T Values

To obtain the real force and torque values, each force value must be divided by the counts per force (cpf)

factor, and each torque value must divided by the counts per torque (cpt) factor. The cpf and cpt factors

can be obtained using the “set” command or from the

Configurations

Configurations Page (config.htm)

).

For example: if a calibration reports 1,000,000 counts per N and the F

z

reports 4,500,000 counts, then the

force applied in the Z axis is 4.5 N.