PROGRAMMING TABBER

22

Tip

: Selection for Backing (

liner

) does not denote type of tab material. Instead, it denotes density of the tab

and liner it is affixed to, as compared to the space between tabs. Rather than thinking of this setting as a

backing description, it is easier to identity if backing (

liner

) has a black bar between each tab or not (

is space

between tabs black or white?

)

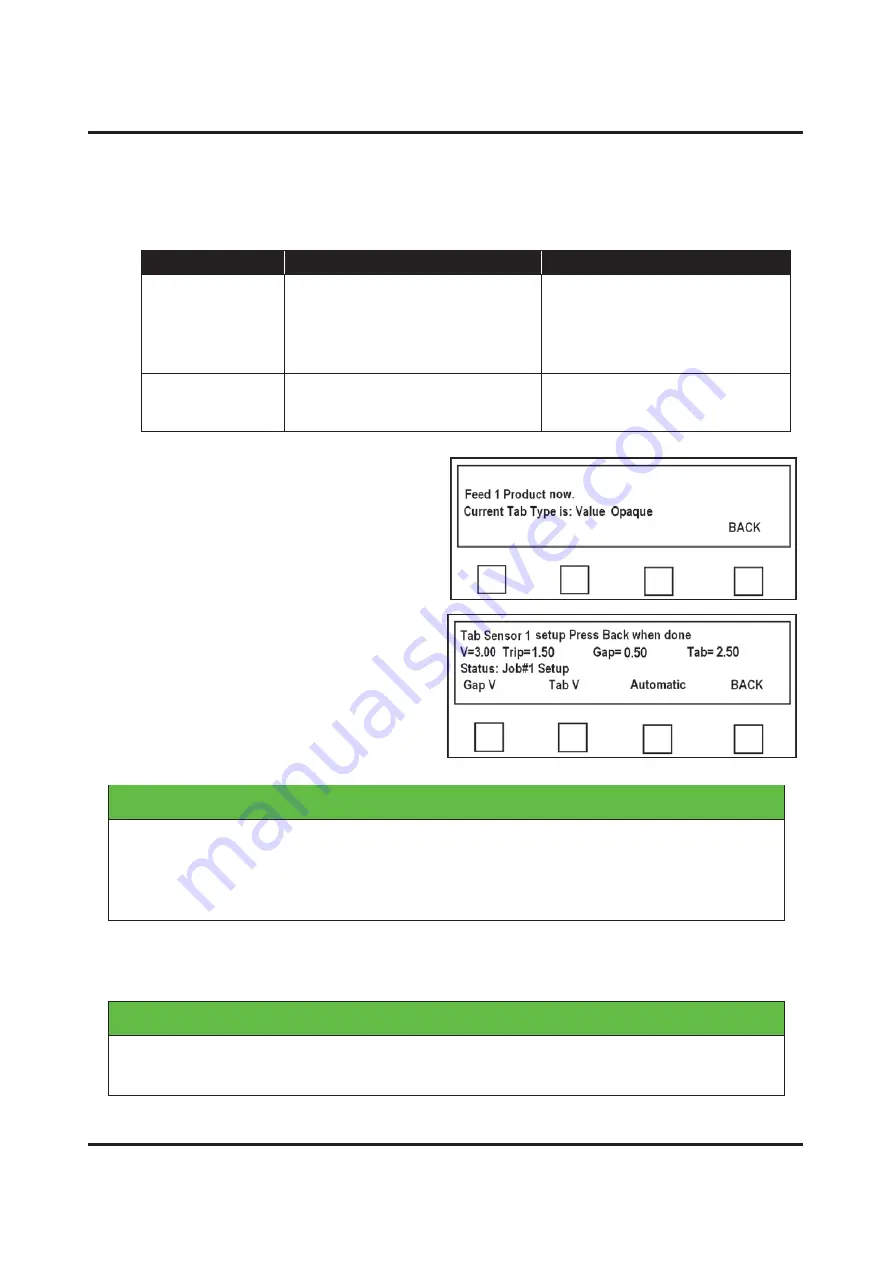

See chart below.

Backing Setting

Color of Space Between Tabs

Detailed Description

Opaque

White space between tabs

Clear or translucent tab material

with black dot, in the liner below

each tab.

Paper tab stock (

white or colored

).

Stamps

Clear

Black space between tabs

Clear or translucent tab material

with black space (

line

), in the liner

between each tab.

Once Tab Type is selected, Tabber

Transport starts and screen at

right appears. Adjust Speed Control on

Tabber up or down until

“

Feed 1

Product now

”

appears in display.

Feed one piece from Feeder into Tabber.

Two or three tabs will be applied to the

piece, then Tabber will stop and display

new V-Tab values. Tab Sensor is now

set up for this tab stock.

IMPORTANT

IN ORDER FOR TABBER TO DISTINGUISH BETWEEN TAB AND BACKING,

VOLTAGE DIFFERENCE BETWEEN GAP V AND TAB V SHOULD BE HALF

OF THE DIFFERENCE BETWEEN THE TWO VOLTAGES. IF TRIP VOLTAGE

IS LESS THAN 0.50 VOLTS, CLEAN THE SENSOR.

7.

Test Tabber for proper operation.

If you experience tab advancement or

positioning problems, verify proper threading, transport setup, media length, tab

type, and tab pitch settings.

IMPORTANT

IF TAB TYPE NEEDS TO BE CHANGED, THEN AUTOMATIC TAB SENSOR

ADJUSTMENT OR PITCH VALUES MAY ALSO NEED REPEATING.