17

Access 600 M802

Installation Instructions

FE6600/BL6600/MP6600 Series Multi-point Lock

FM452 07/20

Copyright © 2017, 2020 ASSA ABLOY Access and Egress Hardware Group, Inc. All rights reserved. Reproduction in whole

or in part without the express written permission of ASSA ABLOY Access and Egress Hardware Group, Inc. is prohibited.

For installation assistance contact Corbin Russwin

1-800-543-3658 • [email protected]

7

Installation Instructions, continued

l

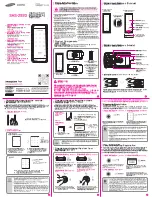

Install Inside Escutcheon Assembly

1. Tighten the inside escutcheon securely to

the mounting plate with the Phillips flat head

machine screws provided. Use the #8-32 x 5/8”

for the top of the escutcheon, and the #8-32 x

1/4” screws for the bottom of the escutcheon

located under the turn lever.

NOTE:

The inside gasket must be used when installing

in an outdoor application.

2. Check that the turn assembly is functional, and

the deadbolt functions properly.

Required for exterior

door applications.

8-32 X 1/4” Phillips

Flat Head Undercut

Machine Screw

8-32 X 5/8” Phillips

Flat Head Undercut

Machine Screw

Inside of Door

m

Install Inside Rose and Inside Lever Assembly

Set

Screw

Inside

Lever

Spindle

Rose

1. Rotate the inside rose counter-

clockwise to seat the threads,

then rotate clockwise to

securely tighten.

2. Slide lever handle onto spindle

until fully seated. The handle

must be horizontal and facing

the hinge side of the door.

3. Push lever onto spindle so

minimum gap is visible.

4. Tighten the set screw securely

with a 1/8” hex wrench.

5. Before closing the door, test

that the lever is functional and

the operation of the latchbolt

and deadbolt is smooth.